Printing without the raft using a glass build plate is a method that can bring several benefits to your work with 3D printers. First, it allows you to save on material used to print the raft, which is then usually thrown away, and it allows you to reduce the time spent on post-processing. Your models gain an improved quality of bottom surfaces as they are printed directly on the smooth glass surface. Such quality is impossible to achieve when printing with standard build plates. However, succeeding at printing without the raft requires learning some rules that will help you reduce the effect of warping and avoid having to reprint your model. Follow the steps described below when using the glass build plate.

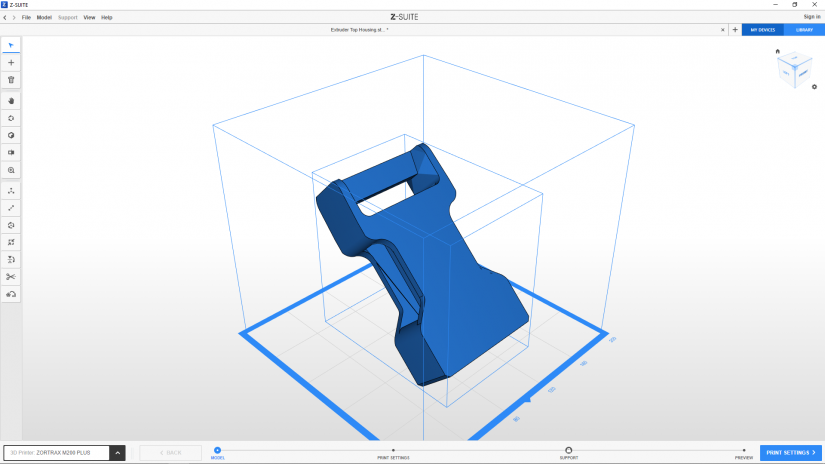

Z-SUITE Settings

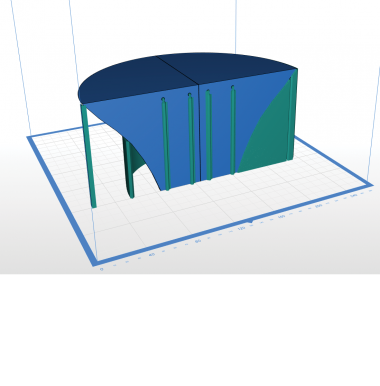

1. Reducing the risk of warping can begin in Z-SUITE. When preparing a model for printing without the raft, remember about proper orientation which can influence the model's adhesion. In general, warping is less likely to occur when you choose positions in which only small surfaces adhere to the glass plate.

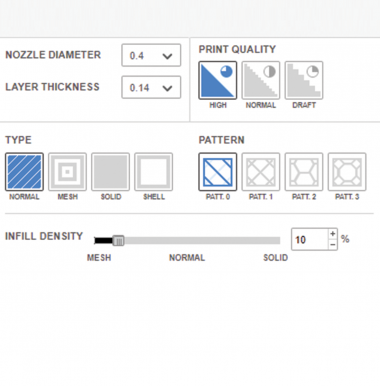

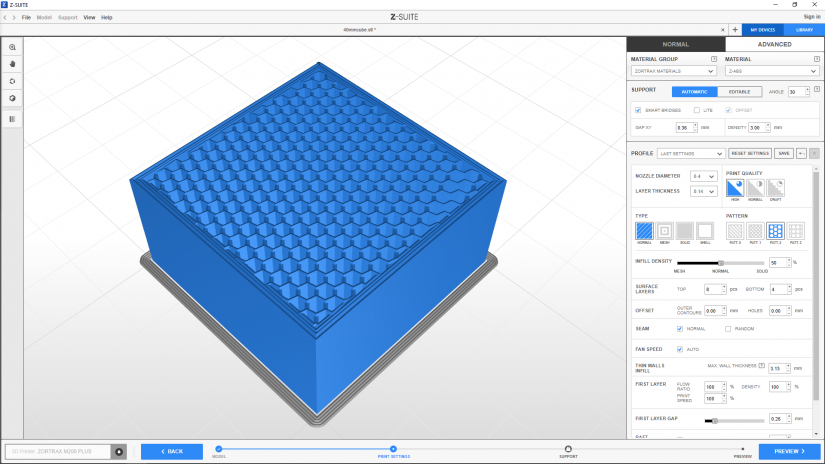

2. Another point worth remembering is adjusting the infill level. If you worry that your model may easily detach from the platform due to its geometry or used material, choose the honeycomb infill pattern. Models with this infill pattern are less likely to warp during the printing process.

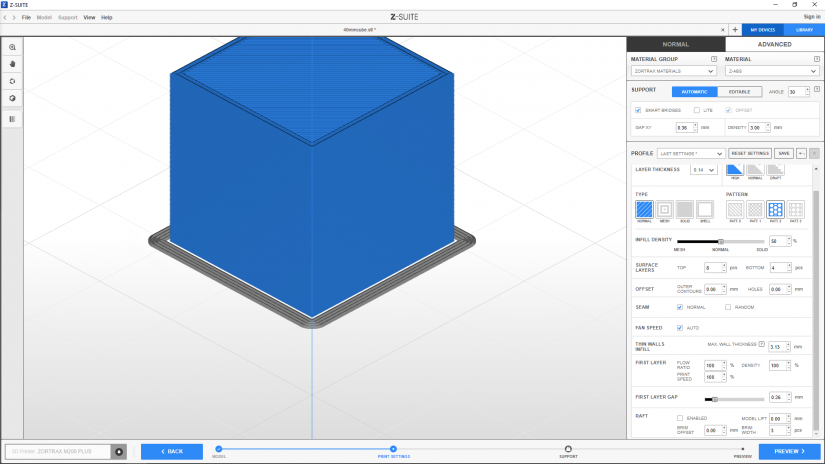

3. If you decide to print without the raft, but you want to provide your model with more protection against warping, it is always good practice to use the Brim option. It is a layer of material that only surrounds the model and is printed along with the model's first layer. If the risk of warping is high, select more Brim paths in the Brim width section.

1. Reducing the risk of warping can begin in Z-SUITE. When preparing a model for printing without the raft, remember about proper orientation which can influence the model's adhesion. In general, warping is less likely to occur when you choose positions in which only small surfaces adhere to the glass plate.

2. Another point worth remembering is adjusting the infill level. If you worry that your model may easily detach from the platform due to its geometry or used material, choose the honeycomb infill pattern. Models with this infill pattern are less likely to warp during the printing process.

3. If you decide to print without the raft, but you want to provide your model with more protection against warping, it is always good practice to use the Brim option. It is a layer of material that only surrounds the model and is printed along with the model's first layer. If the risk of warping is high, select more Brim paths in the Brim width section.

Calibration & Maintenance

Before you start to print without the raft, you have to properly calibrate the platform in your printer. This procedure makes it less possible for prints to deform during the printing process. When using the glass plate, you have to carry out the manual calibration. It involves adjustments of the platform’s position in relation to the nozzle by tightening or loosening the platform screws.

Detailed instructions are displayed on the screen during the calibration. To start the calibration, open the Tools menu, then select Platform and then Manual Calibration.

You can use the Automatic Calibration option, but only with the M300 Dual.

Also, clean the glass plate thoroughly from the remaining material, dust and dirt before each printing process. To achieve the best possible results, the plate should be as smooth as possible.

Temperature Control

When protecting your prints from the warping effect, it is very important to control the temperature in the print room. The temperature should be maintained within the range of 21 and 28° C [70 – 82° F].

If you’re unable to provide the proper temperature, isolate the printing chamber from the surroundings with the side covers set and a HEPA Cover. These accessories improve the printing conditions and protect your prints from temperature differences which could lead to warping.

This manual provides instructions on how to install side covers in your printer and this short film explains all the features of the HEPA Cover.

Plate Adhesives

If you’re still having problems with platform adhesion, try coating the glass plate with a layer of either a glue stick or a spray adhesive.

When using a glue stick, remember that the applied layer should be thin and even to retain the smoothness of the printing area.

When using a spray adhesive, at first unplug the heatbed cable and remove the platform from the printer. Remember that the spray has to be applied while the platform is cool. Spray the plate from a distance of 15-30 cm [5.9-11.8 in]. Next, wait until the solvent evaporates before installing the platform back in the printer.