Zortrax Endureal is equipped with a capacitive sensor that is used in the printer to establish the proper distance between the nozzles and the platform by measuring the electrical capacity between these components. Due to various reasons, capacitive sensing may get distorted. In this article, we explain at which aspects you should look when errors or problems with platform calibration occur.

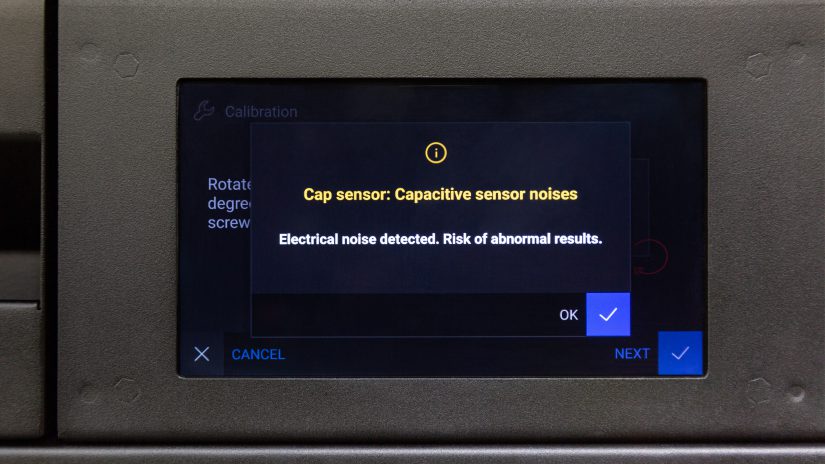

Capsensor Error

The most common issues with the cap sensor occur during platform calibration. Electrical noises block proper cap sensor functioning. The machine stops the process and displays a warning about abnormal results. Printing is possible, however, probing may take a longer time, and calibration results will be inaccurate.

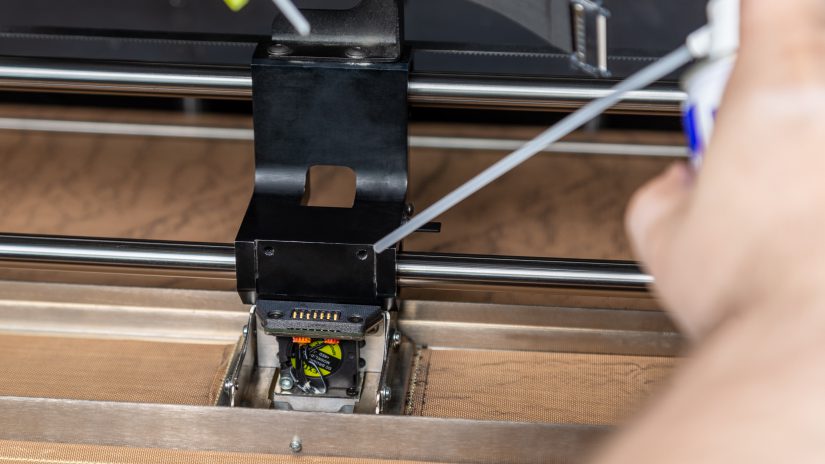

Pogo Pins Inspection

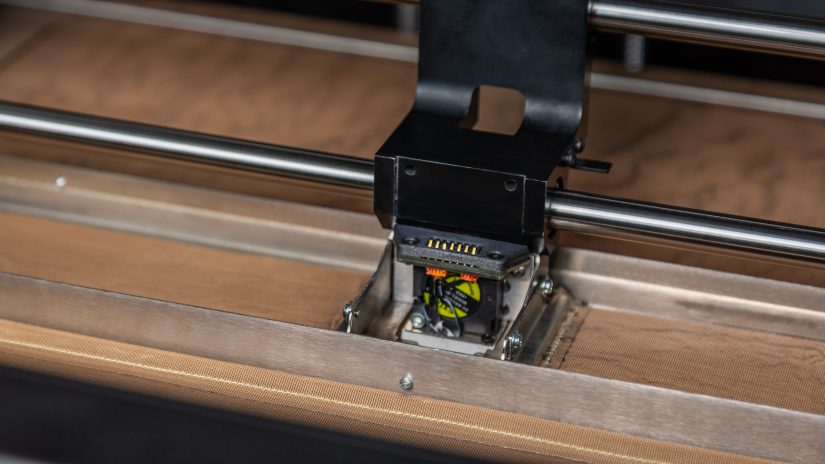

The first step that should be taken into account is checking the condition of cap sensor module pogo pins. The first picture shows the normal condition of pogo pins; the second one shows bent pins.

If the pins are not damaged, it is advisable to clean them just with compressed air (picture 3).

In order to get access to the pogo pins, it is necessary to remove the extruder. Follow the first three steps of this manual: Extruder Replacement.

If cleaning the pogo pins did not help, or the pins are bent, move to the next step.

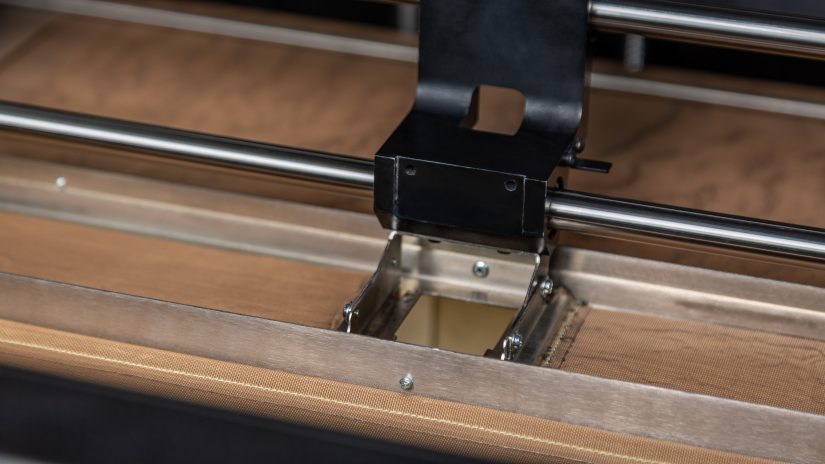

Cap Sensor Module Replacement

It may happen that even if the cap sensor seems to be visually in perfect condition, one of its electrical paths has been damaged. As a result, the whole cap sensor module needs replacement.

In order to see how to replace the cap sensor, follow this manual: Cap Sensor Module Replacement.

Extruder Replacement

If the problem has not been resolved, the last component that needs replacement is the extruder.

In order to replace the extruder, follow all the steps from this manual: Extruder Replacement.