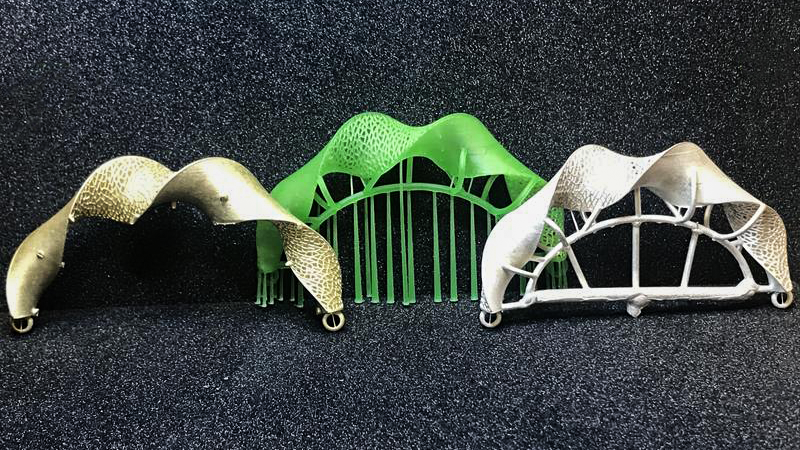

PowerCast Opaque and PowerCast Burn are special 100% ash-free castable resins that have been formulated for jewelry and dentistry. Their qualities allow you to achieve the perfect printing and direct casting quality when creating any type of jewelry, surgical guides or denture prototypes. The resins are easy to use and post-process, requiring almost no special treatment.

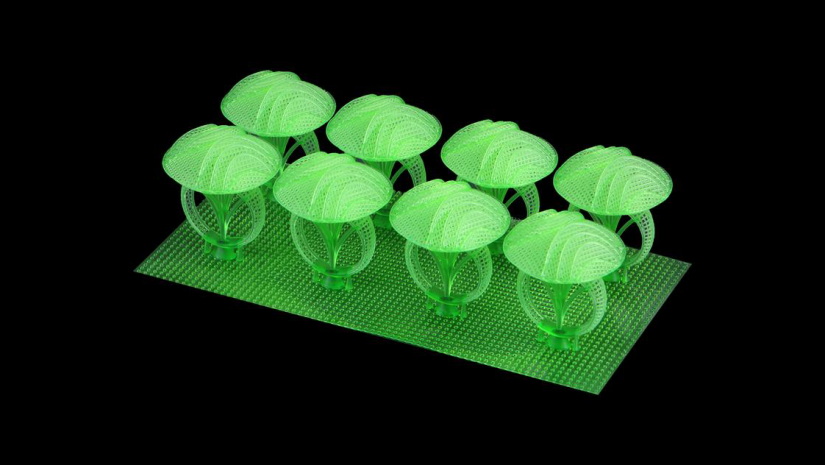

PowerCast Opaque

Features

- Perfect surface and print quality for DLP 3D printers,

- 100% ash-free burnout for direct casting of jewelry. You may easily cast 21k, 18k, 14k gold or silver,

- Can be used for any type of jewelry including engraving, smooth surface, high details or filigree jewelry,

- No need for post-curing: only wash with ethyl alcohol, dry with air, and then it is ready for casting,

- Use of standard burnout cycle, no need for special treatment,

- Not smelly or dangerous for health.

Process of washing, drying before casting

- Wash your prints with ethyl alcohol (ethanol) – you can use 96% ethyl alcohol

- The best way is to wash first 2-3 times by spraying ethyl alcohol and blowing dry air with a compressor.

- Do not leave the prints inside alcohol for a long time as this may increase the shrinkage of your prints afterwards.

- Do not use isopropyl alcohol as it is more reactive. Ethyl alcohol would be much better to clean without reacting with the resin.

- There is no need to carry out UV curing before casting.

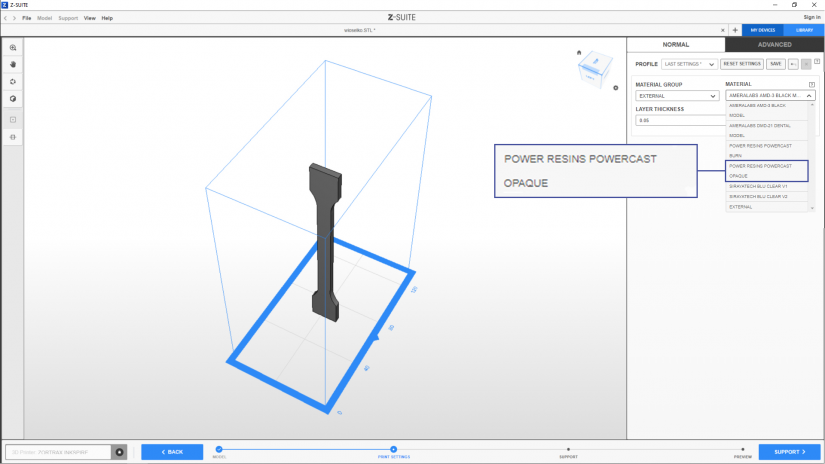

Print Settings

First, change the Material group to External, and then select the POWER RESINS POWERCAST OPAQUE from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.

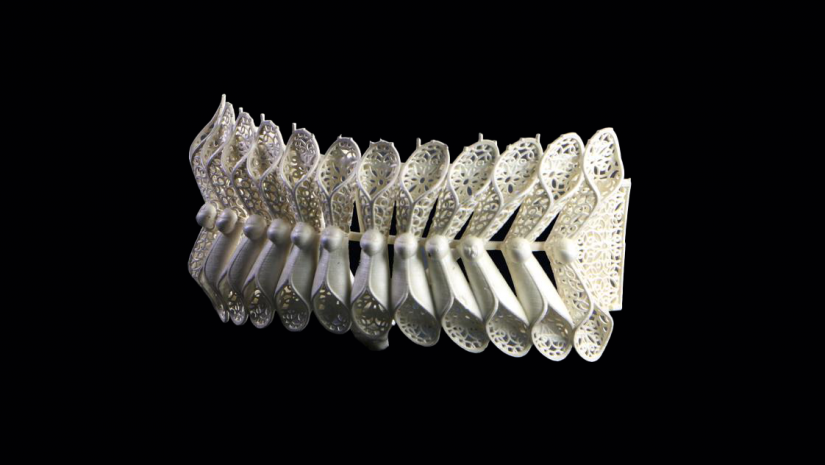

PowerCast Burn

Features

- 100% ash-free burnout for direct casting,

- Suitable for jewelry and dental casting,

- Can be used for any type of jewelry including heavy, European jewelry or filigree designs,

- Perfect casting quality so there is a minimum need of polishing after casting,

- Use of standard burnout cycle.

Process of washing, drying before casting

- Wash your prints with ethyl alcohol (ethanol) – you can use 96% ethyl alcohol

- The best way is to wash first 2-3 times by spraying ethyl alcohol and blowing dry air with a compressor.

- Do not leave the prints inside alcohol for a long time as this may increase the shrinkage of your prints afterwards.

- Do not use isopropyl alcohol as it is more reactive. Ethyl alcohol would be much better to clean without reacting with the resin.

- There is no need to carry out UV curing before casting.

Print Settings

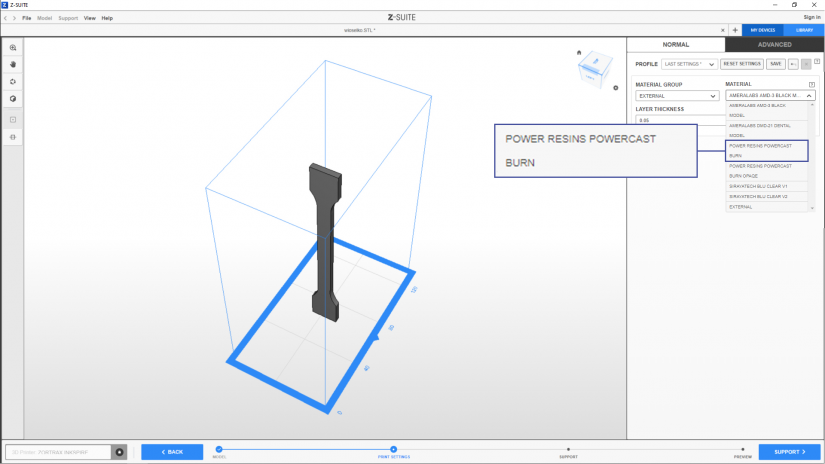

First, change the Material group to External, and then select the POWER RESINS POWERCAST BURN from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.