From the 2.15.0 Z-SUITE update, it is possible to print with resins delivered by HARZ Labs. The update includes printing profiles for a wide choice of specialized resins suitable for dental applications as well as creative projects and concept modeling. The available resins have various properties, helping professionals at work and allowing them to easily implement their ideas. This article provides details about the resins’ features and instructions for the printing process.

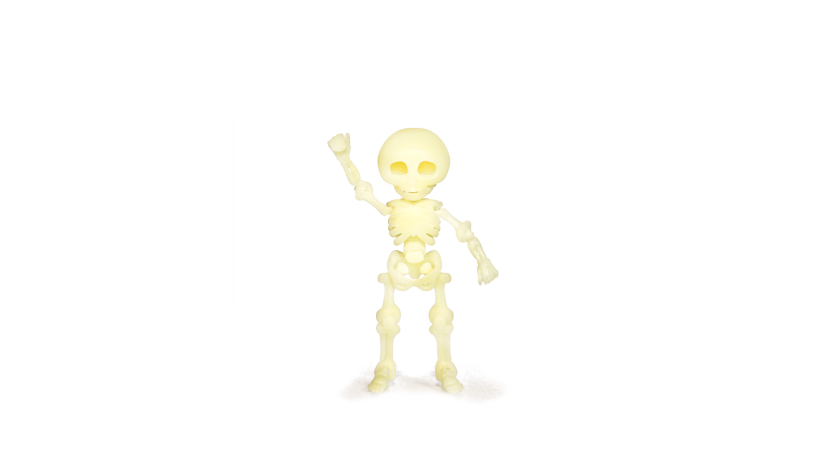

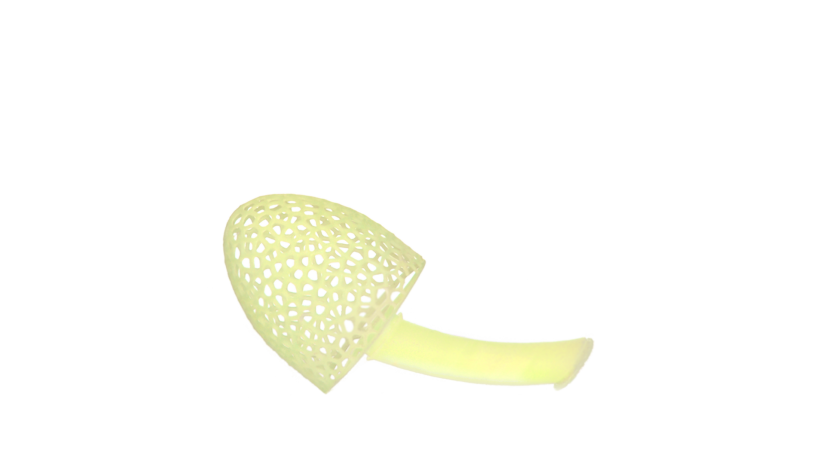

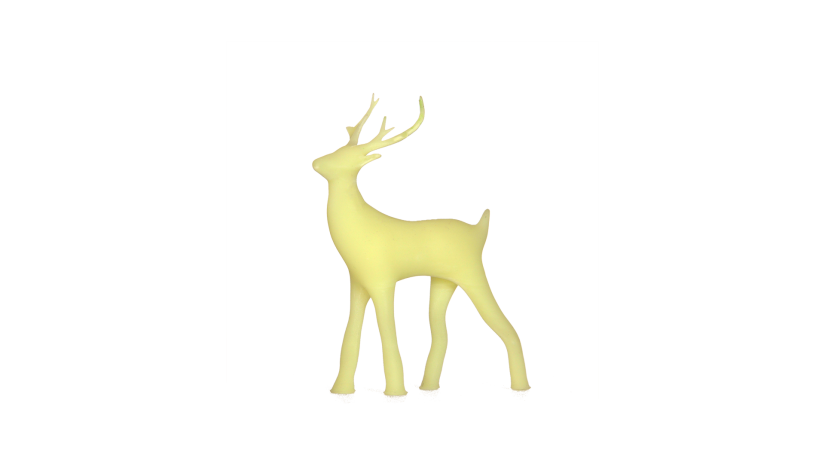

Art Glow

Features

HARZ Labs ART Glow resin has been designed for printing of decorative products. Its ingredients include a special glowing pigment, which ensures that models have bright green glow in the dark for up to 2 hours.

- Resin has relatively low viscosity, which decreases time needed for model cleaning and provides maximum accuracy,

- Resin is odorless and causes no irritation, so you can work with natural ventilation without special technique,

- Shrinkage less than 0.5 % gives your models high dimensional accuracy,

- Resin does not contain solvents, volatile monomers, or irritating compounds. Fumes, odor and allergic reactions are not expected,

- Resin keeps a luminescence effect up to 2 hours after full “charging”.

Properties

- Appearance – Opaque liquid

- Color – Yellow

- Odor – None

- Luminescence – Up to 2h

- Hardness – 80 – 92 Shore D

- Shrinkage – <0.5%

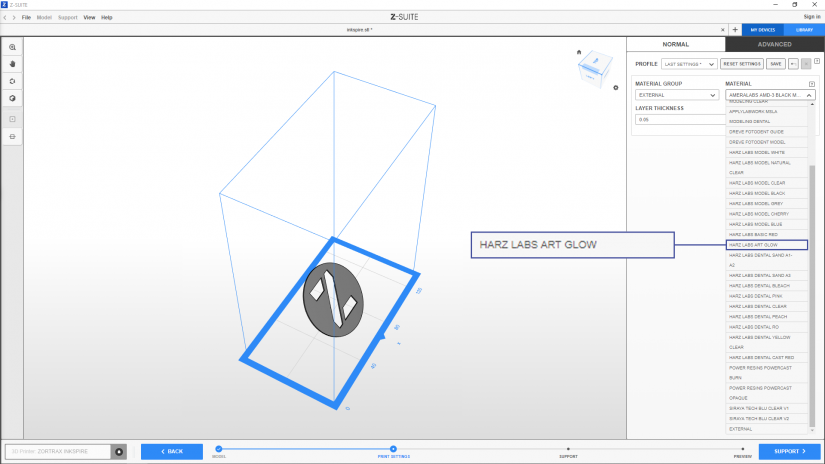

Print Settings

First, change the Material Group to External, and then select the HARZ Labs Art Glow from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.

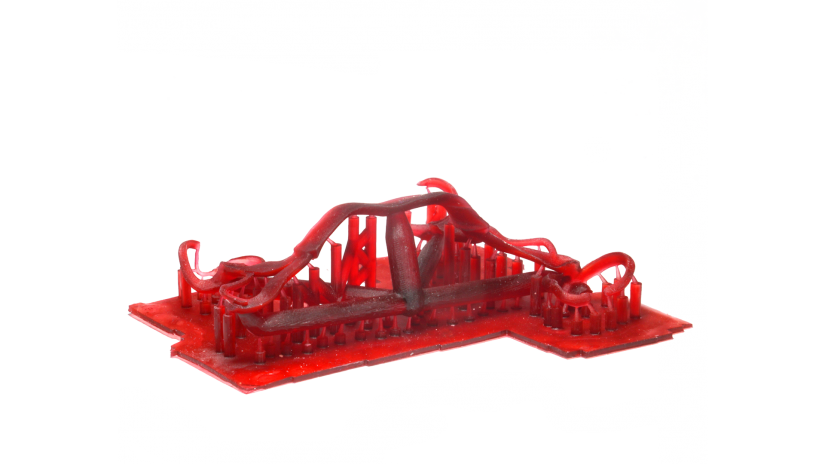

Basic

Features

HARZ Labs Basic is a good choice for beginners in 3D printing. The absence of odor and low toxicity makes the resin ideal for use in the office, schools and universities. It is easy to operate due to low viscosity – it is easier to fill the tank, filter the liquid, and clean printed parts.

- Resin has relatively low viscosity, which decreases time needed for model cleaning and provides maximum accuracy,

- Resin is odorless and causes no irritation, so you can work with natural ventilation without special technique,

- 2.5% shrinkage gives your models high dimensional accuracy,

- Resin does not contain solvents, volatile monomers, or irritating compounds. Fumes, odor and allergic reactions are not expected,

- Resin is hard and tough, showing 82 Shore D hardness; you will not easily damage your models when removing them from the platform,

- Resin is very stable; no sedimentation and gel formation is expected.

Properties

- Appearance – Colored transparent liquid

- Color – Red

- Odor – None

- Viscosity (Brookfield) – 0.6 – 0.8 Pa*s

- Tensile strength – 20 N/mm2

- Elongation at break – 6 – 7%

- Hardness – 80 – 85 Shore D

- Shrinkage – 2.5%

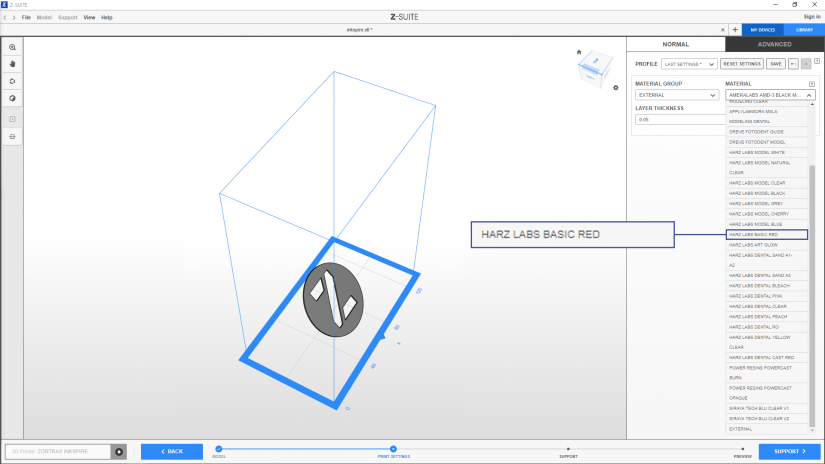

Print Settings

First, change the Material Group to External, and then select the HARZ Labs Basic Red from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.

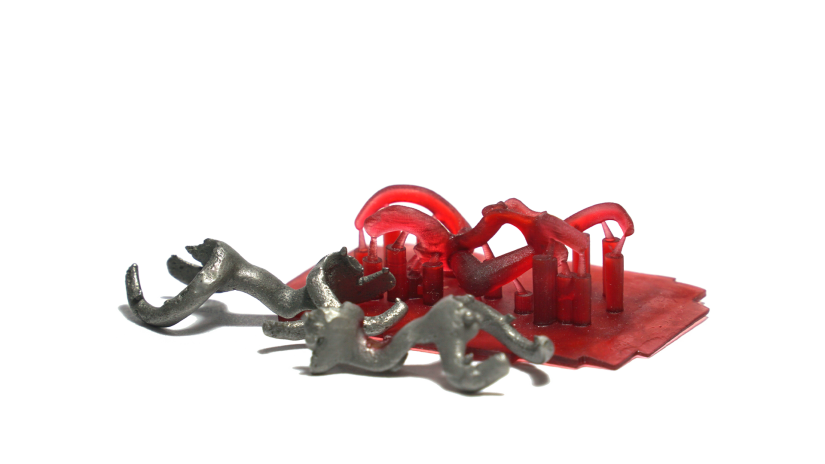

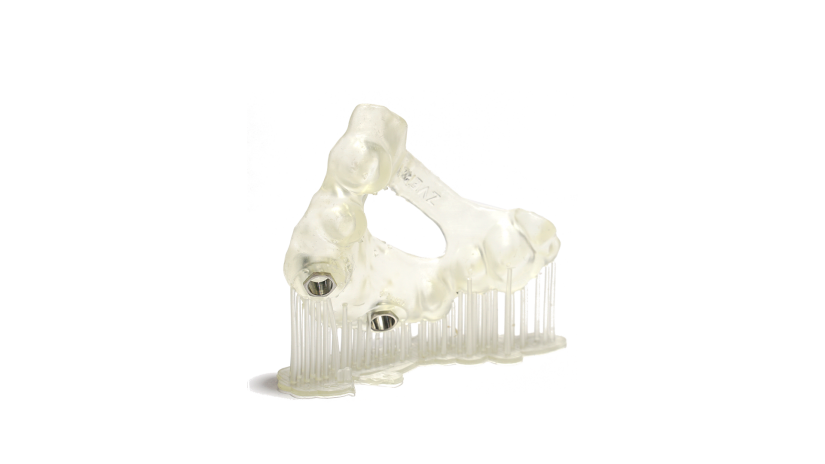

Dental Cast

Features

HARZ Labs Cast is excellent for direct casting of dental implants, such as metal and ceramic crowns and bridges. Almost zero ash content (less than 0.1%) and thermoplastic properties make the resin suitable for dentistry.

The resin has been designed to burn out in a quick cycle at high temperature to reduce production time.

- Provides high precision printing; dental implants fit easily after casting,

- Resin is odorless and causes no irritation, so you can work with natural ventilation without special technique,

- Shrinkage less than 1% gives your models high dimensional accuracy,

- Close to zero ash content (<0.1%), and high strength make it possible to cast precise metal and ceramic products,

- Resin is very stable; no sedimentation and gel formation is expected,

- Thermoplastic behavior of the resin provides melting in a wide temperature range (250 – 300° C) to give very smooth surface of casted models.

Properties

- Appearance – Colored transparent liquid

- Color – Red

- Odor – Low

- Viscosity (Brookfield) – 0.2 – 0.4 Pa*s

- Ash content – <0.1%

- Hardness – 40 – 50 Shore D

- Shrinkage – <1%

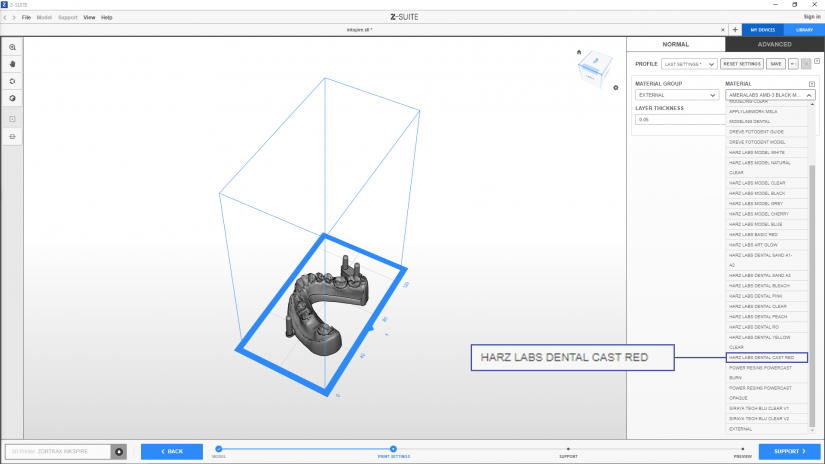

Print Settings

First, change the Material Group to External, and then select the HARZ Labs Dental Cast Red from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.

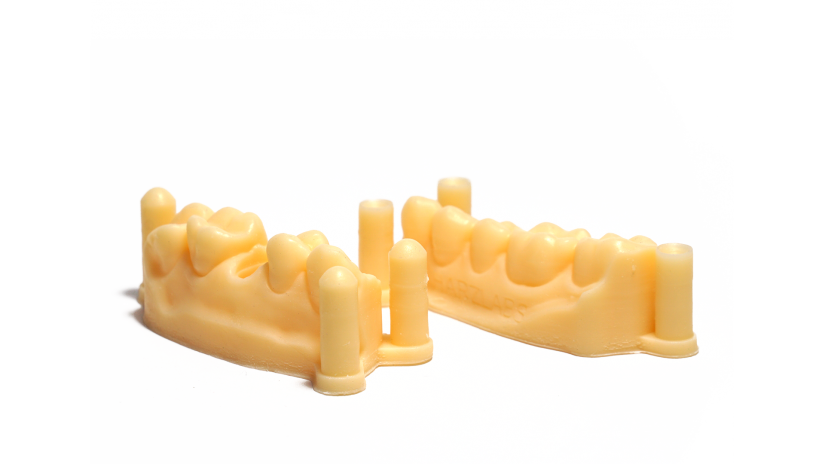

Dental Clear

Features

HARZ Labs Dental Clear is a hard PMMA-like clear resin designed for printing models used in dentistry, where transparency is one of the main goals.

It allows users to print demonstration models for operation planning, aligners, or surgical guides.

- Resin has relatively low viscosity, which decreases time needed for model cleaning and provides maximum accuracy,

- Resin is odorless and causes no irritation, so you can work with natural ventilation without special technique,

- Shrinkage less than 0.5 % gives your models high dimensional accuracy,

- Produced from biocompatible raw material used in photopolymer teeth fillings. Meets the standard ISO 10993,

- High transparency and low yellowing effect after post-treatment,

- Very high hardness and tensile strength.

Properties

- Appearance – Transparent liquid

- Color – Clear transparent

- Odor – None

- Viscosity (Brookfield) – 0.9 – 1 Pa*s

- Tensile strength – 60 N/mm2

- Elongation at break – 4 – 6%

- Hardness – 90 – 92 Shore D

- Shrinkage – <0.5%

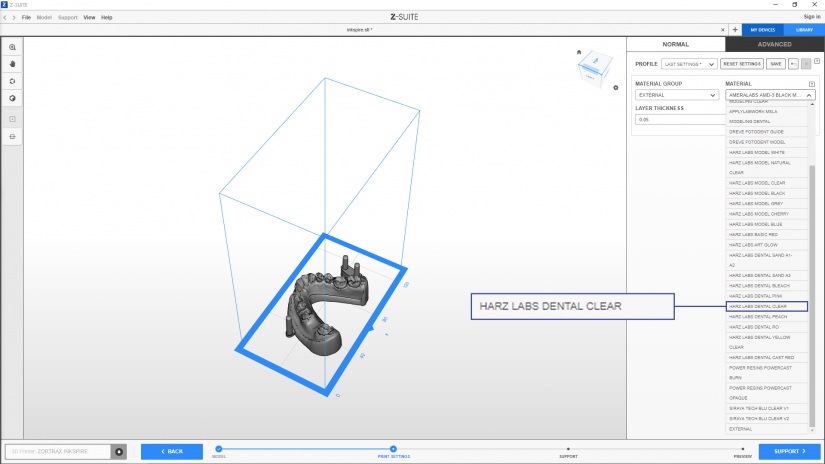

First, change the Material Group to External, and then select the HARZ Labs Dental Clear from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.

Dental Peach

Features

HARZ Labs Dental Peach is a matt pale orange resin made of biocompatible raw materials used in UV-cured dental fillings. It is characterized by high hardness (87 Shore D), high tensile strength, and stability to mechanical and thermal stress. The resin has low odor and does not contain harmful monomers; it can be used in any work environment.

- Very precise resin, suitable for dental applications where models need to fit perfectly,

- Resin is odorless and causes no irritation, so you can work with natural ventilation without special technique,

- Shrinkage less than 0.5 % gives your models high dimensional accuracy,

- Produced from biocompatible raw material used in photopolymer teeth fillings. Meets the standard ISO 10993,

- Models has long-term stability under 100° C, but short-term stability up to 180° C. It can be used for films thermosetting.

Properties

- Appearance – Opaque liquid

- Color – Pale orange

- Odor – None

- Viscosity (Brookfield) – 1 – 1.2 Pa*s

- Tensile strength – 60 N/mm2

- Elongation at break – 4 – 6%

- Hardness – 85 – 87 Shore D

- Shrinkage – <0.5%

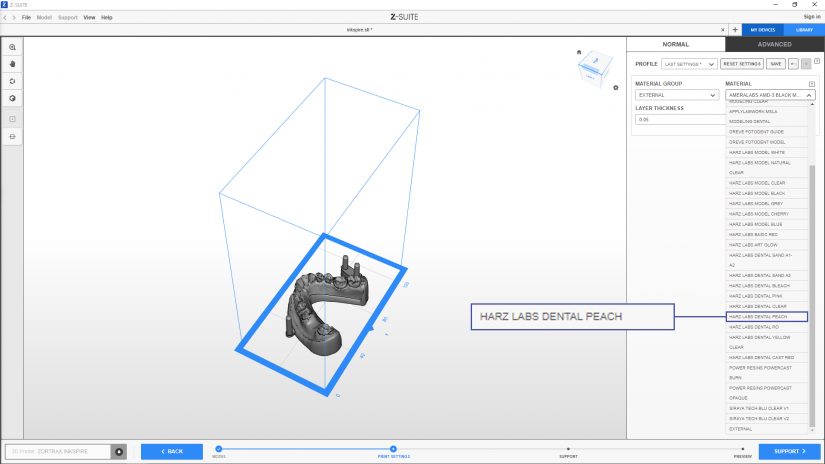

Print Settings

First, change the Material Group to External, and then select the HARZ Labs Dental Peach from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.

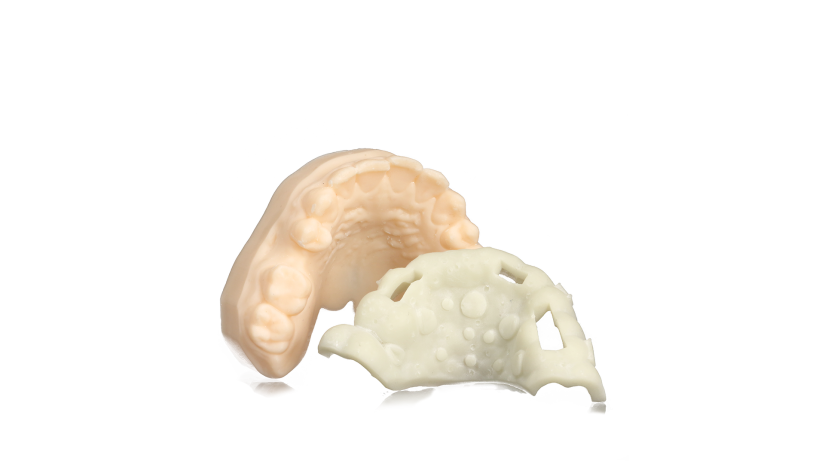

Dental Pink

Features

HARZ Labs Dental Pink is a PMMA-like resin made of biocompatible raw materials. It is semi-transparent and its color resembles gums. It is characterized by high hardness (87 Shore D), high tensile strength, and stability to mechanical stress. It is recommended for printing dental models of gum color, such as gingiva masks. The resin has low odor and does not contain harmful monomers; it can be used in any work environment.

- Very high hardness, tensile strength, abrasion and scratch resistance due to ceramic fillers,

- Resin is odorless and causes no irritation, so you can work with natural ventilation without special technique,

- Shrinkage less than 0.5% gives your models high dimensional accuracy, and they don’t change their size after post-curing,

- Produced from biocompatible raw material used in photopolymer teeth fillings. Meets the standard ISO 10993,

- Resin is resistant to solvents, aggressive inorganic agents, such as acids and alkalis,

- Pigments and fillers are well-stabilized. Sedimentation, flocculation, or foaming are not expected.

Properties

- Appearance – Opaque liquid

- Color – Semi-transparent pink

- Odor – None

- Viscosity (Brookfield) – 1.0 – 1.2 Pa*s

- Tensile strength – 60 N/mm2

- Elongation at break – 3 – 4%

- Hardness – 87 – 90 Shore D

- Shrinkage – <0.5%

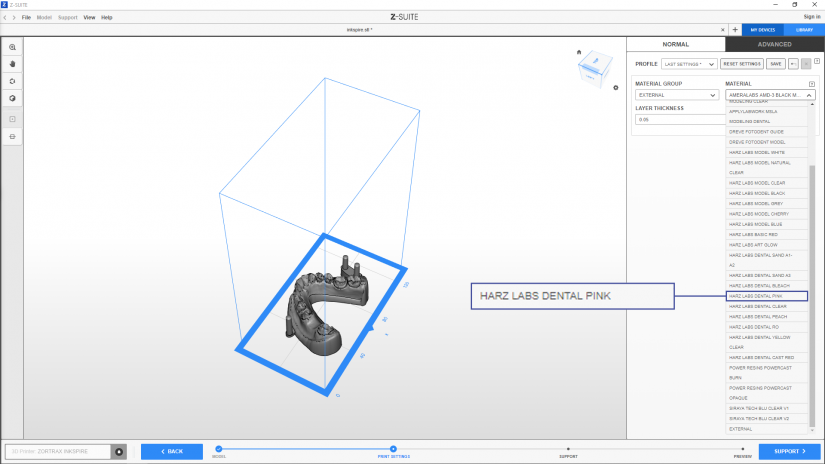

Print Settings

First, change the Material Group to External, and then select the HARZ Labs Dental Pink from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.

Dental RO

Features

HARZ Labs Dental RO contains a special radiopaque filler for obtaining a clear picture when conducting a CT scan. The resin is available in white, and is made from biocompatible raw materials, which are durable and accurate. It has been designed to produce CT patterns that would facilitate the planning of surgeries.

- Produced from biocompatible raw material used in photopolymer teeth fillings. Meets the standard ISO 10993,

- Resin is odorless and causes no irritation, so you can work with natural ventilation without special technique,

- Shrinkage less than 0.5% gives your models high dimensional accuracy,

- Provides high precision printing; dental implants fit easily after casting,

- The printed parts are radiopaque, which makes it possible to use them as templates during CT scans.

- Appearance – Opaque liquid

- Color – White

- Odor – None

- Viscosity (Brookfield) – 1.1 – 1.5 Pa*s

- Tensile strength – 30 N/mm2

- Elongation at break – 2 – 4%

- Hardness – 75 Shore D

- Shrinkage – 0.5%

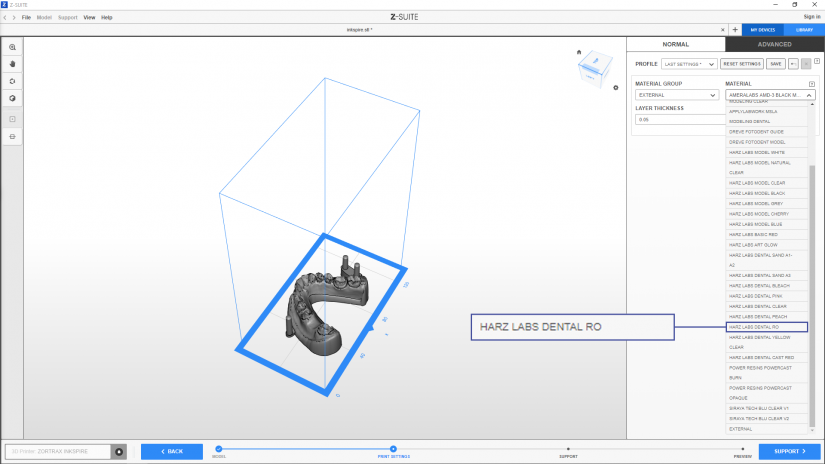

Print Settings

First, change the Material Group to External, and then select the HARZ Labs Dental RO from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.

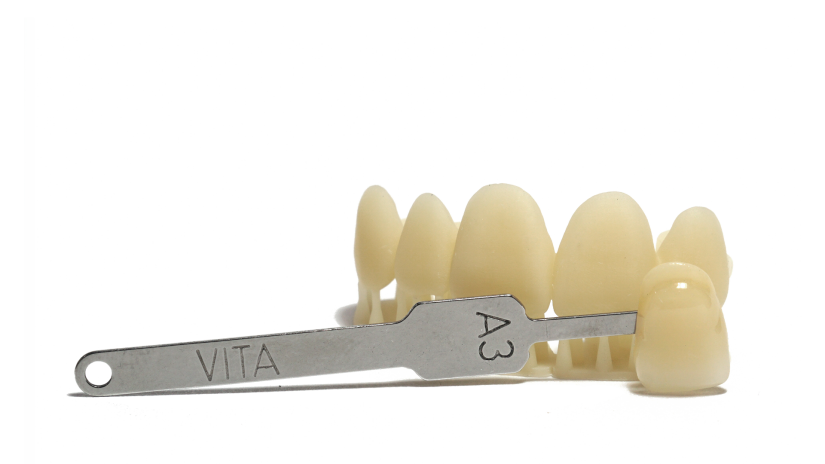

Dental Sand A1-A2; A3; Bleach

Features

HARZ Labs Dental Sand A1-A2, A3; Bleach are PMMA-like micro-filled composite resins, made of biocompatible raw materials. They are characterized by high hardness (90 Shore D), high tensile strength, and stability to mechanical stress and chemicals. They are recommended for printing temporary crowns and bridges. The resins have low odor and do not contain harmful monomers; they can be used in any work environment.

- Very high hardness, tensile strength, abrasion and scratch resistance due to ceramic fillers,

- Resins are odorless and cause no irritation, so you can work with natural ventilation without special technique,

- Depending on post-curing conditions, A1 or A2 colors are achievable. Resins are stable for a long time even in aggressive agents,

- Produced from biocompatible raw material used in photopolymer teeth fillings. Meet the standard ISO 10993,

- Resins are resistant to solvents, aggressive inorganic agents, such as acids and alkalis,

- Pigments and fillers are well-stabilized. Sedimentation, flocculation or foaming are not expected.

Properties

- Appearance – Opaque liquid

- Color – Beige

- Odor – None

- Viscosity (Brookfield) – 1.2 – 1.5 Pa*s

- Tensile strength – 60 N/mm2

- Elongation at break – 3 – 4%

- Hardness – 90 – 92 Shore D

- Shrinkage – <0.5%

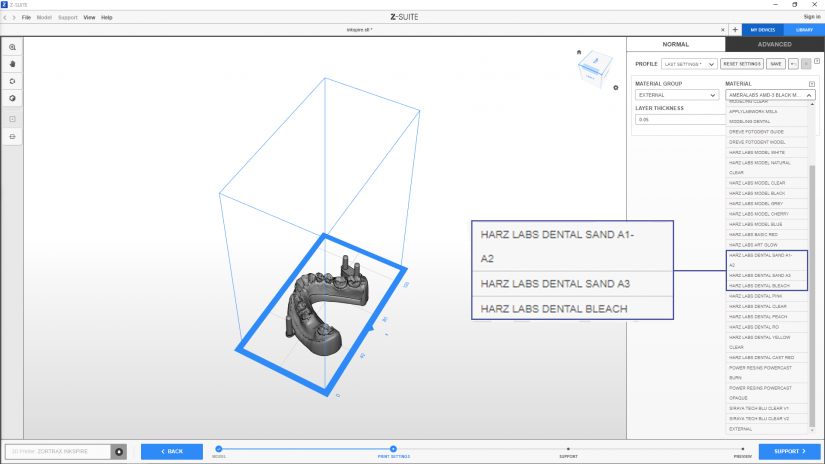

Print Settings

First, change the Material Group to External, and then select the HARZ Labs Dental Sand A1-A2 or HARZ Labs Dental Sand A3 from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.

Dental Yellow Clear

Features

HARZ Labs Dental Yellow Clear is a hard PMMA-like resin made of biocompatible raw materials used in UV-cured dental fillings. It is characterized by high hardness (92 Shore D), high tensile strength, and stability to mechanical stress. It is recommended for printing surgical guides and master-model printing. The resin has low odor and does not contain harmful monomers; it can be used in any work environment.

- Models has long-term stability under 100° C, which makes it possible to use both hot and cold silicone molds during casting processes,

- Resin is odorless and causes no irritation, so you can work with natural ventilation without special technique,

- Shrinkage less than 0.5 % gives your models high dimensional accuracy,

- Produced from biocompatible raw material used in photopolymer teeth fillings. Meets the standard ISO 10993,

- Resin is very stable; no sedimentation and gel formation is expected,

- Very high hardness and tensile strength.

Properties

- Appearance – Colored transparent liquid

- Color – Transparent yellow

- Odor – None

- Viscosity (Brookfield) – 1 – 1.2 Pa*s

- Tensile strength – 60 N/mm2

- Elongation at break – 4 – 6%

- Hardness – 90 – 92 Shore D

- Shrinkage – <0.5%

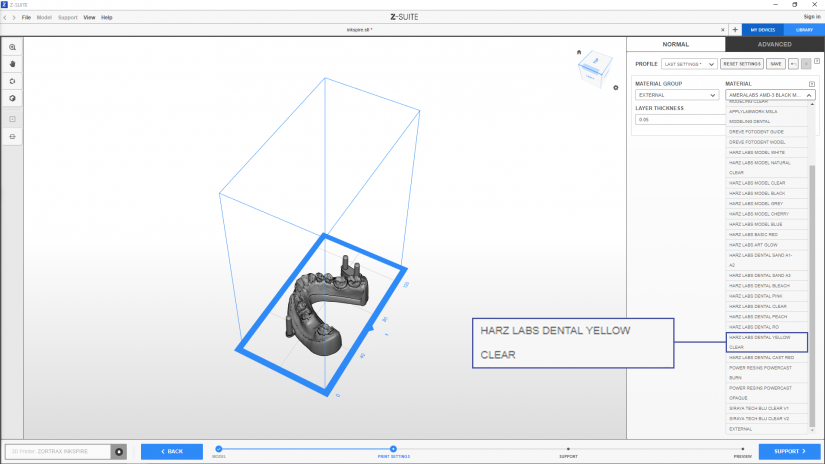

Print Settings

First, change the Material Group to External, and then select the HARZ Labs Dental Yellow Clear from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.

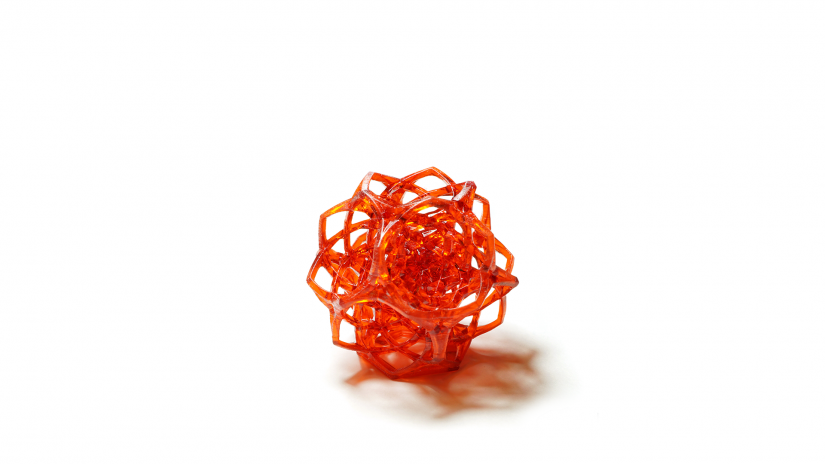

Model

Features

HARZ Labs Model is hard and elastic the same time after being fully cured. This allows users to print functional parts that can withstand mechanical stresses. Printed parts are resistant to high temperatures (up to 100° C), which makes it possible to use them to create silicone molds by hot and cold vulcanization. The resin works with two-component silicones on both platinum and tin catalysts.

- Models has long-term stability under° 100 C, which makes it possible to use both hot and cold silicone molds during casting processes,

- Resin is odorless and causes no irritation, so you can work with natural ventilation without special technique,

- Shrinkage less than 0.5% gives your models high dimensional accuracy,

- Resin does not contain solvents, volatile monomers, or irritating compounds. Fumes, odor and allergic reactions are not expected,

- Resin is very stable. No sedimentation and gel formation is expected,

- Wide range of colors. Models made with Clear and White resins can be tinted.

Properties

- Appearance – Colored transparent liquid

- Color – Clear, Natural Clear, Grey, Black, White, Cherry, Blue

- Odor – None

- Viscosity (Brookfield) – 0.8 – 1 Pa*s

- Tensile strength – 45 N/mm2

- Elongation at break – 4 – 6%

- Hardness – 87 – 92 Shore D

- Shrinkage – <0.5%

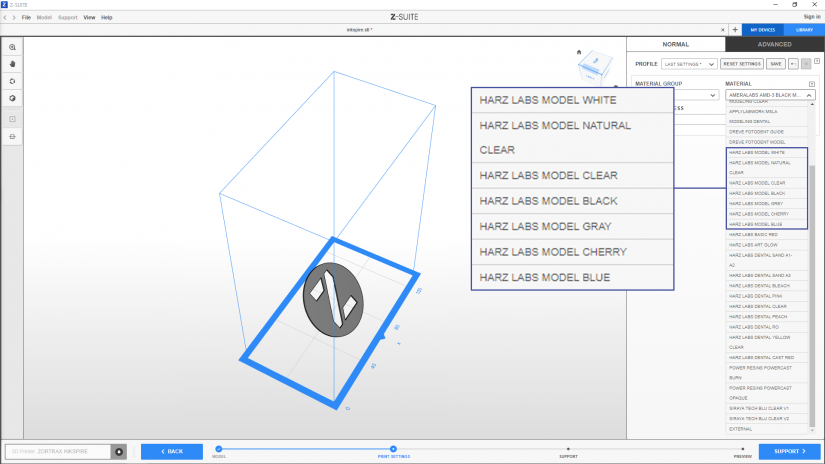

Print Settings

First, change the Material Group to External, and then select the adequate color from the drop-down list.

Next, set the Layer thickness with which you are going to print your model. This parameter determines the height of each layer. Finer layers provide better surface quality but make the printing process more time-consuming.