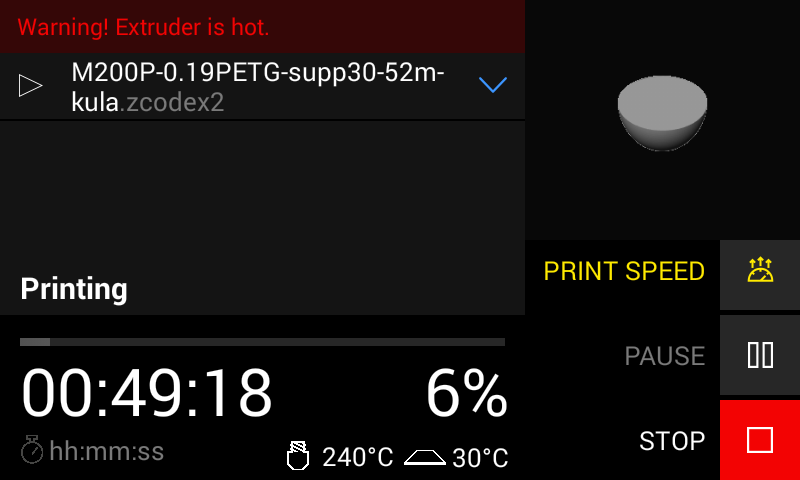

The Print Speed Adjustments is a firmware tool that allows you to accelerate the printing process, and as a result, significantly reduce the time needed to print a given model. Depending on the model’s geometry, quality of print may decrease. However, the print speed can be changed on the spot, even during the printing process, so parts that need to be detailed can be printed at the standard speed. As a result, you can easily control the speed of printing and the level of details of your models.

Speed Adjustments before the Printing Process

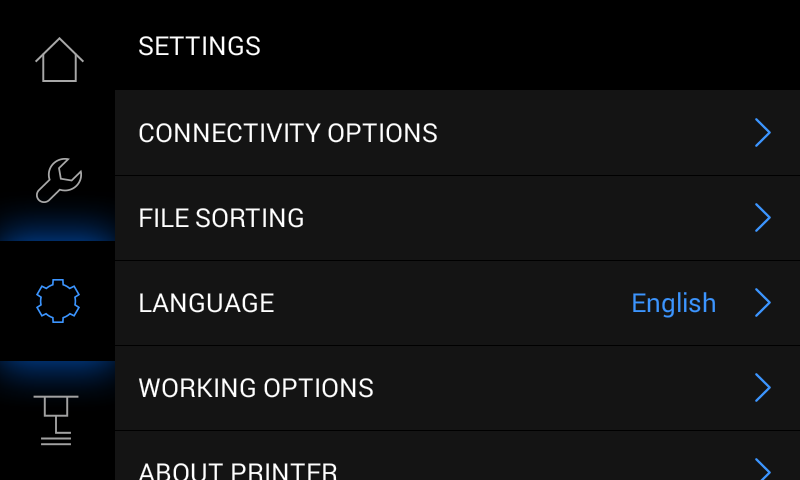

1. Open the Settings menu and select Working Options.

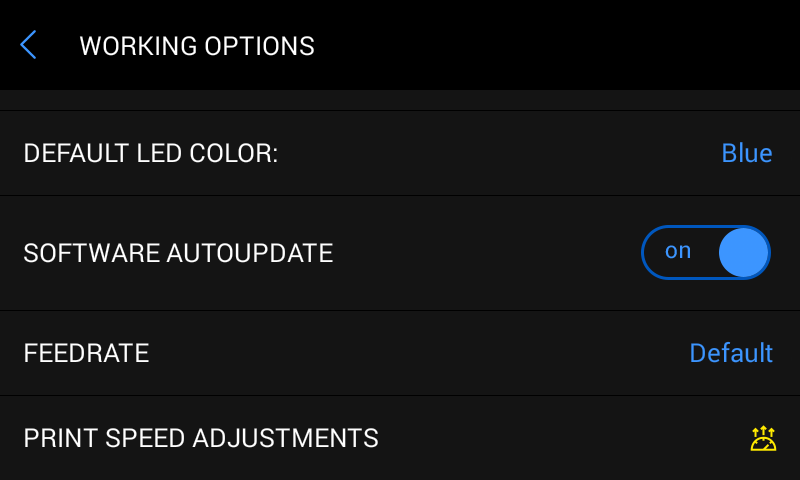

2. Next, scroll down the menu and choose Print Speed Adjustments.

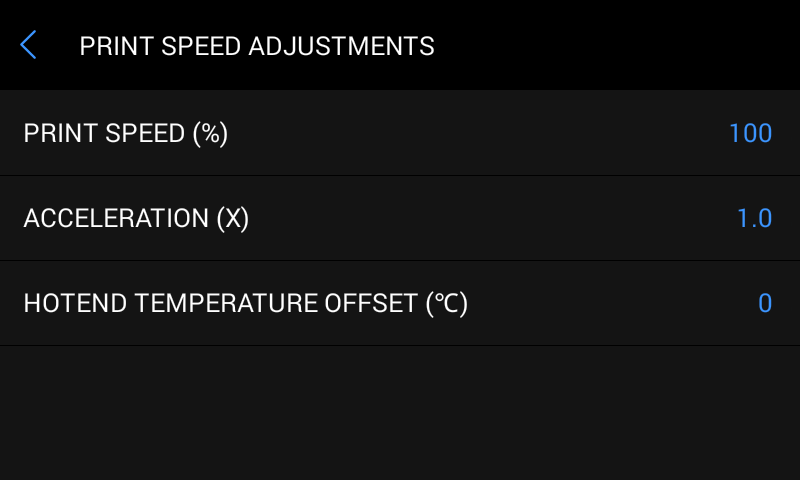

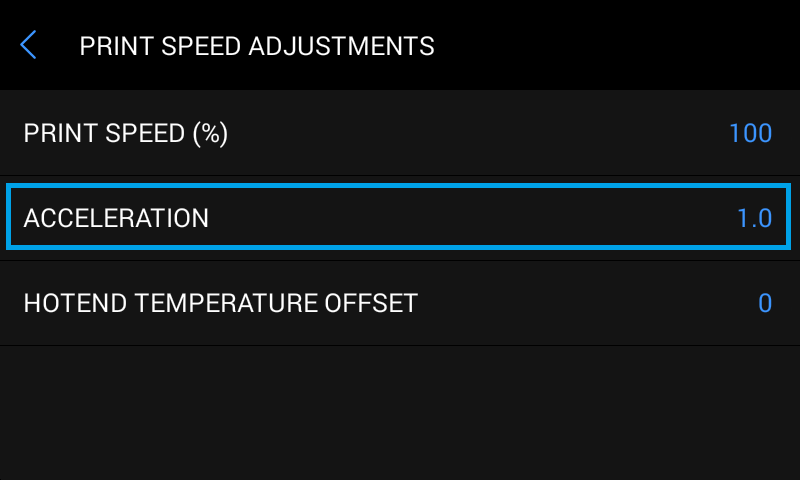

3. The menu will show three options that can be adjusted.

Definitions

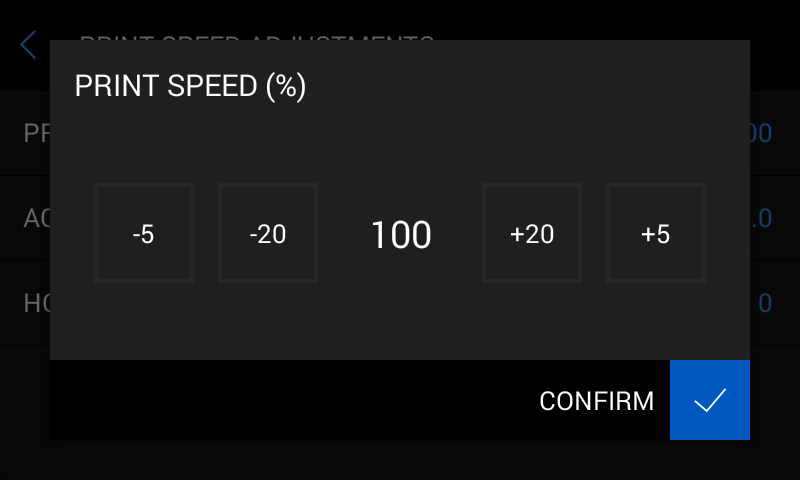

1. Print speed – this is the speed of the extruder head moving in XY axes while printing. The default value is 100%. You can go up to 300%. Remember that the printing speed of raft, infill, supports, contours is not identical, so when you change the print speed to 300%, it means that each of them will be printed 3 x faster than their default values

2. Acceleration – this option determines how fast the extruder accelerates after changing direction of printing. It can gain the speed slowly or more rapidly. The values are: x0.75, x1.0, x1.5, x2.0. The default one is x1.0. We recommend using x1.5.

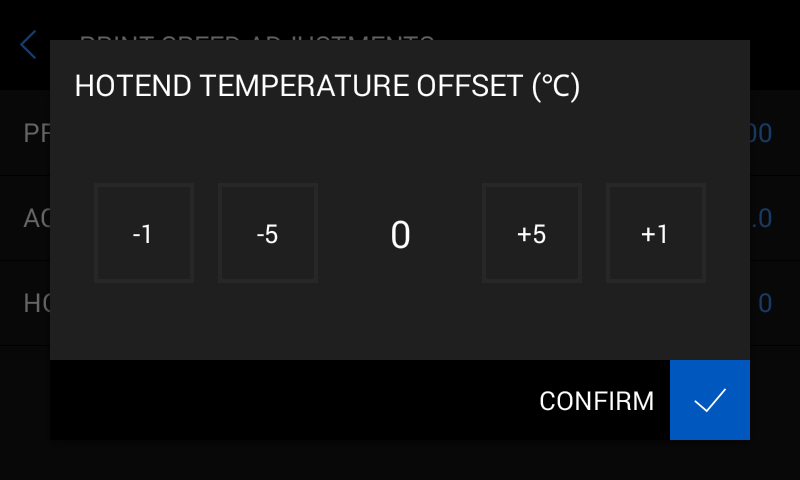

3. Hotend Temperature Offset – printing in a high speed mode might require increasing the hotend temperature. Faster movements in the XY directions, and having the default hotend temperature, might result in material deficiency on the print. In order to ‘’keep up’’ with extruding while printing with very high speed, you can increase the extrusion temp. (5 degrees Celsius - more is not recommended)).

1. Print speed – this is the speed of the extruder head moving in XY axes while printing. The default value is 100%. You can go up to 300%. Remember that the printing speed of raft, infill, supports, contours is not identical, so when you change the print speed to 300%, it means that each of them will be printed 3 x faster than their default values

2. Acceleration – this option determines how fast the extruder accelerates after changing direction of printing. It can gain the speed slowly or more rapidly. The values are: x0.75, x1.0, x1.5, x2.0. The default one is x1.0. We recommend using x1.5.

3. Hotend Temperature Offset – printing in a high speed mode might require increasing the hotend temperature. Faster movements in the XY directions, and having the default hotend temperature, might result in material deficiency on the print. In order to ‘’keep up’’ with extruding while printing with very high speed, you can increase the extrusion temp. (5 degrees Celsius - more is not recommended)).

FAQ

Is the print speed the same for each M-series printer?

No, it is not, which means that each device will achieve different acceleration values and printing speeds.

Are you considering implementing the Print Speed Adjustments feature for standard materials (e.g. ABS, Z-Ultrat) on Endureal?

At this point, this feature will only be available for selected desktop devices. If we decide to implement it on other machines, we will keep you informed.

Can the Print Speed Adjustments option be used when printing on a glass platform?

When printing on a glass platform, we use the “raftless” mode, which, unfortunately, will not work well with fast printing. Therefore, we recommend using only the perforated plate when using the Print Speed Adjustments option.