The problem of contours that can easily peel off in an FDM 3D print occurs when the outer wall/perimeter is not bonded to the infill and creates a small, visible gap between the two areas. This defect can significantly reduce functionality, durability and aesthetics of printed parts, as well as make them unusable. However, it is possible to counteract this effect in Z-SUITE before the printing process begins. There are some print settings that you can adjust when preparing your model to make sure the contours will not detach from the infill. Follow the steps described below to see how to change the necessary settings. Make sure you’re using the appropriate Z-SUITE version: updates 2.12.1 or newer / 2.14.0 BETA or newer.

Offset Settings in Z-SUITE

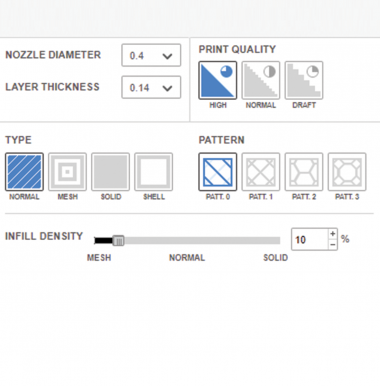

You can counteract the problem with contours at the stage of preparing your model for 3D printing. In the Print settings step, open the Advanced menu and go to the Offset section. Next, decrease the Contour-infill gap value. The default contour-infill gap value is 0.4 mm.

This option is available in Z-SUITE updates: 2.12.1 or newer, and 2.14.0 BETA or newer.

Remember that changing this setting may also slightly change the external dimensions of your final print.