Specially dedicated Zortrax printing materials maximize the benefits of 3D printing with Zortrax devices. These thermoplastic materials are in the form of filaments either wound on a spool or enclosed in a cartridge. Each material has different properties, and can easily be adapted to a wide range of needs and applications. Moreover, most of the materials can be mechanically and chemically post-processed. Zortrax offers a wide range of materials, which are available at: zortrax.com

This article summarizes the properties of each material from our offer.

Z-ABS

Z-ABS is a versatile and economic material which perfectly matches the needs of users who begin their work with 3D printing as well as professionals who want to make savings on in-house prototyping. Z-ABS is characterized by high shrinkage, therefore, large and thick-walled models are prone to warping and should be designed sensibly.

Z-ABS is ideal for printing small elements, for creative applications, conceptual models, gadgets or figurines, and for prototypes with moderate functional requirements. What is more, it’s suitable for many methods of post-processing, such as painting, gluing, spackling, grinding, sandblasting, etc.

Z-ABS models can be easily smoothed using the

acetone vaporizing method (see acetone vaporizing article).

There are two types of Z-ABS in the offer. Read and follow the guidelines from this article before using Z-ABS.

Dedicated for: M200, M200 Plus, M300 Plus, Inventure* and M300 Dual**

*single-extrusion mode only

**both single- and dual-extrusion mode

Z-ASA Pro

Z-ASA Pro is a thermoplastic which is durable and exhibits superior resistance to external factors, including UV radiation and extreme weather conditions. Using Z-ASA Pro, you can 3D print models and prototypes which will withstand changing temperature, humidity or sunlight, and keep their initial shape and excellent aesthetics. Z-ASA Pro is a way to go for prototypes of sporting equipment and specialized tools, fadeproof models for outdoor purposes or unvarnished automotive elements.

Moreover, models printed with Z-ASA Pro can be post-processes in acetone vapors.

Dedicated for: M200, M200 Plus, M300, M300 Plus, Inventure* and M300 Dual**

*single-extrusion mode only

**both single- and dual-extrusion mode

Z-ESD

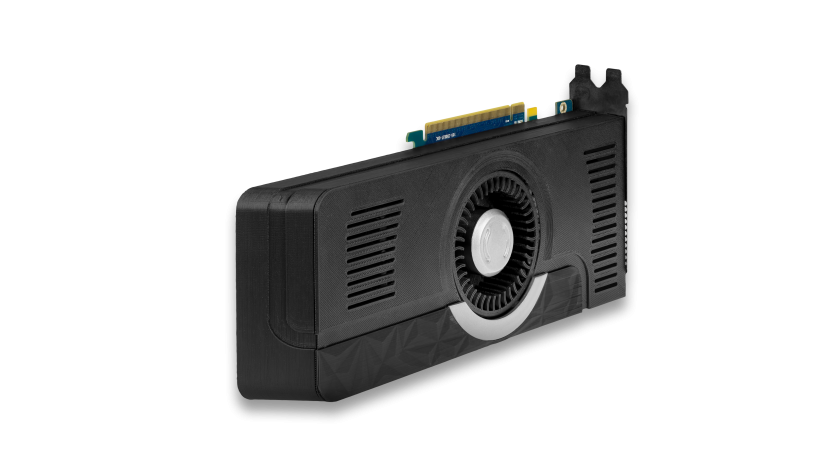

Z-ESD is a material which perfectly fits the needs of the industrial sector, especially the electrical and electronics industries. It is durable, warpage resistant and, most importantly, it provides protection against electrostatic discharge which can be particularly damaging to electrical and electronic equipment. Electrostatic protection is crucial when working with highly sensitive electronics. Models printed with Z-ESD are strong, stable and resistant to chemical substances, such as salts, acids, alkalis. Z-ESD models have a semimat finish which gives them a really attractive look.

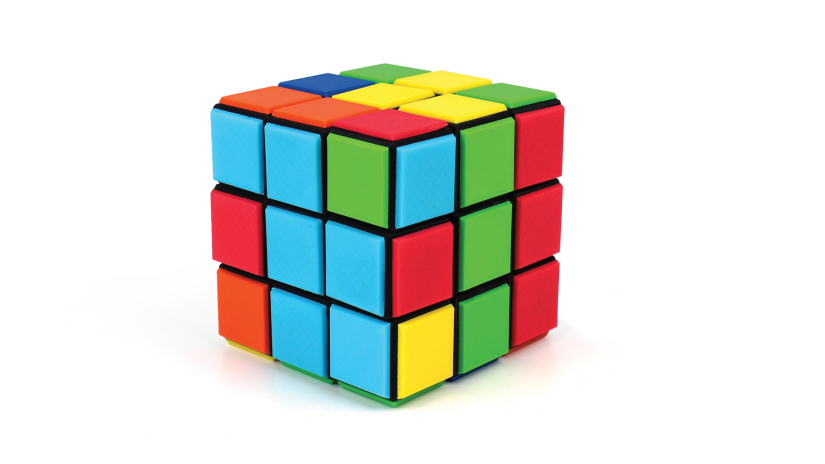

Z-ESD is perfect for printing functional objects that will actually control and prevent electrostatic discharge, that is, elements and casings holding printed circuit boards or expansion cards in computers or electrical conductivity meters.

Dedicated for: M200, M200 Plus, M300, M300 Plus, Inventure* and M300 Dual

*dual-extrusion mode only with Z-SUPPORT Premium

Z-FLEX

Z-FLEX is a material with unique properties that will allow you to successfully print objects with a rubber-like texture. This material exhibits high impact and abrasion resistance, but it also offers resistance to chemical substances, such as gasoline, ethyl alcohol, butane, and carbon monoxide. In addition, Z-FLEX has strong adhesion between individual layers which gives your models enhanced durability. These qualities make Z-FLEX perfect for creating elastic parts, including hinges, gaskets or prototypes of tires, which will undergo frequent bending and will be tested in industrial environments.

Dedicated for: M200 Plus, M300 Plus, Inventure*, M300 Dual*

*single-extrusion mode only

Z-GLASS

Z-GLASS is a material with unparalleled properties that will allow you to successfully replace brittle glass elements in your functional prototypes and show what is within them. Its low shrinkage level makes it possible to 3D print defect-free models which will be durable and scratchproof, including automotive and electronics objects. With Z-GLASS, you can create light-transmitting objects that will remain unaffected by heavy exposure to light (high UV resistance) or chemicals. All these advantages make this material ideal not only for industrial sector but also for creating interior design elements. Z-GLASS is available in five shades: four colors and natural transparent.

Printing with Z-GLASS requires using the hotend V2 in the Zortrax M200.

Dedicated for: M200, M200 Plus, M300, M300 Plus, Inventure* and M300 Dual*

*both single- and dual-extrusion modes

Z-HIPS

Z-HIPS is a versatile thermoplastic perfect for 3D printing prototypes which can be used in thorough tests before starting the production processes. It exhibits a high level of hardness, allowing you to complete durable prints without compromises on their quality. Z-HIPS models acquire a unique and smooth surface and resemble elements manufactured with mass production plastics, therefore, imitate complete consumer products or end-use parts. Z-HIPS is also fully suited for creating prototypes of mechanical parts or casing elements for performance tests.

Dedicated for: M200, M200 Plus, M300, M300 Plus, M300 Dual*

*single-extrusion mode only

Z-NYLON

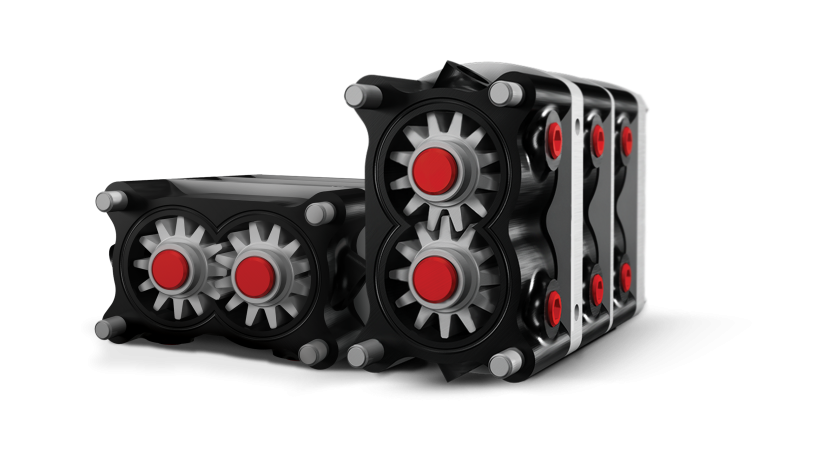

Z-NYLON (PA12) is a versatile material that exhibits high impact and abrasion resistance. Its properties also include resistance to high temperatures and moderate chemical substances. All these characteristics will bring the highest benefit to engineers and users from various industry fields during the preparation of functional prototypes. What’s more, models printed with Z-NYLON can be post-processed with tools meant for machining metals and can easily be painted. Z-NYLON is fully suited for technical and mechanical parts, such as toothed gears, guides, slide bearings, or functional tools.

Dedicated for: M200 Plus, M300 Plus, Inventure* and M300 Dual*

*single-extrusion mode only

Z-PCABS

Z-PCABS is based on ABS and polycarbonate (PC). Its advantages include high mechanical durability, and resistance to various factors, including high temperatures, UV rays, and chemicals. Z-PCABS is perfectly suited for industrial use as it allows you to test your prototypes and end-use parts regardless of extreme conditions. You will benefit from this fusion of materials while creating housings of everyday tools, constructional elements of various equipment, and automotive components which will remain stable and fully functional over time. However, Z-PCABS has high shrinkage in comparison with other materials. That’s why, it’s better to use the side covers set during the printing process.

Dedicated for: M200, M200 Plus, M300 Plus

Z-PEI 9085

Z-PEI 9085 is a durable, aerospace-grade polymer with strength-to-weight ratio comparable to aluminum 6061. The filament consists of polyetherimide and a polycarbonate copolymer blend. Z-PEI 9085 exhibits excellent thermal properties which can be retained in temperatures reaching 170° C. The most notable properties of Z-PEI 9085 are very low FST (Flame, Smoke, Toxicity) and a UL 94 V-0 flammability rating. That’s why, the filament is widely adopted in automotive and aerospace industries. Flame retardancy of the material makes it suitable for fabricating aircraft interiors, ductwork, and electrical enclosures. What’s more, Z-PEI 9085 is resistant to automotive fluids and alcohols which enables printing tools that have to work with lubrication.

Dedicated for: Endureal – both single- and dual-extrusion modes

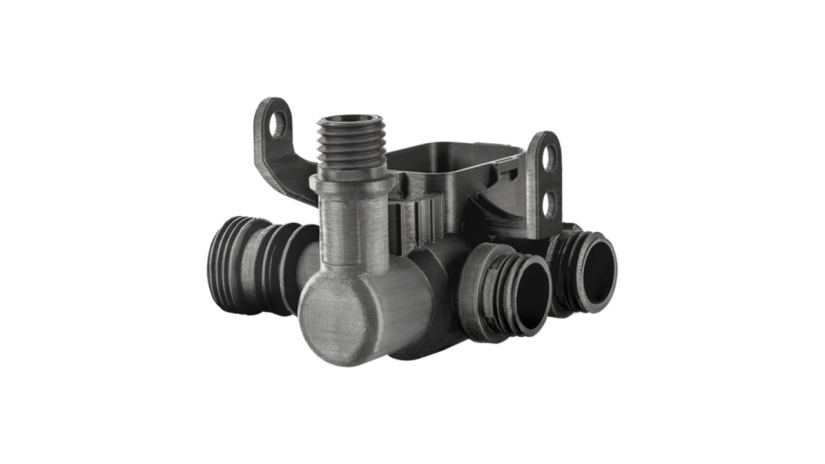

Z-PEI 1010

Z-PEI 1010 is a blend of PEI which is slightly stronger than Z-PEI 9085 and with higher heat deflection temperature. The material can withstand temperatures reaching 208 °C. It is also harder than Z-PEI 9085 which makes it perfect for scenarios where high rigidity is of paramount importance. Moreover, it offers broad chemical resistance to automotive fluids, fully halogenated hydrocarbons, alcohols, and aqueous solutions among others.

Due to chemical resistance, Z-PEI 1010 can be used to seals or piping components that won’t contaminate the products they come in contact with. Halogenated hydrocarbons, in turn, are used in heating or cooling systems, and machinery for cleaning metals.

Dedicated for: Endureal – dual-extusion mode only

Z-PETG

Z-PETG is an industrial-grade material which offers outstanding resistance to impact of time, chemicals as well as UV rays. Its properties include durability and tensile strength. Z-PETG is the best choice for prototypes which will undergo real crash tests, including industrial trials that involve oils and greases. Z-PETG is base on the popular PET and glycol. This helped to eliminate the brittleness of models and boost their durability. Z-PETG will support your innovative ideas with its low shrinkage, and allow you to create prototypes of complex mechanisms, automotive parts, and manufacturing tools unaffected by chemicals.

Dedicated for: M200, M200 Plus, M300, M300 Plus, Inventure* and M300 Dual*

*both single- and dual-extrusion modes

Z-PLA

Z-PLA is an ecological material which is commonly used in the 3D printing industry. It is derived from natural resources and, as a result, it is biodegradable and environment-friendly. Its main attributes include very low shrinkage and a high degree of hardness. With no limits to shapes and complexity of models, Z-PLA gives you the possibility to print high-quality parts, detailed conceptual objects, and even consumer goods. Its smooth surface will also provide exceptional aesthetics for mock-ups, decorative and display elements, and educational models.

Dedicated for: M200 Plus, M300 Plus, Inventure*, M300 Dual*

*both single- and dual-extrusion modes

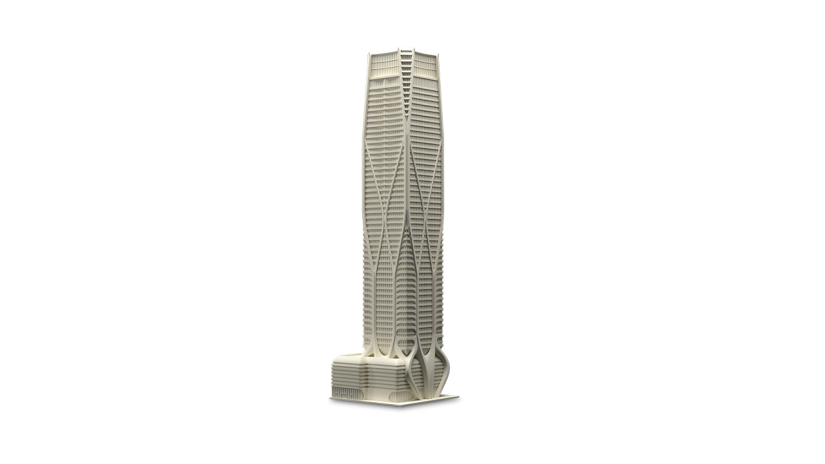

Z-PLA Pro

Z-PLA Pro is a material which has been developed using a natural and recyclable PLA as one of the components. Due to the highly reduced shrinkage, this material allows you to print intricate shapes and objects rich in details with high dimensional accuracy. Z-PLA Pro exhibits exquisite surface quality that closely resembles the texture of gypsum casts. The excellent aesthetics of the 3D printed models make Z-PLA Pro perfect for supporting artistic projects and creating sizable architectural designs as well as mock-ups in a convenient and eco-friendly way.

In order to avoid problems while printing with Z-PLA Pro, it is advisable to use a separate hotend only for this particular material.

Dedicated for: M200, M200 Plus, M300, M300 Plus, Inventure*, M300 Dual*

*both single- and dual-extrusion modes

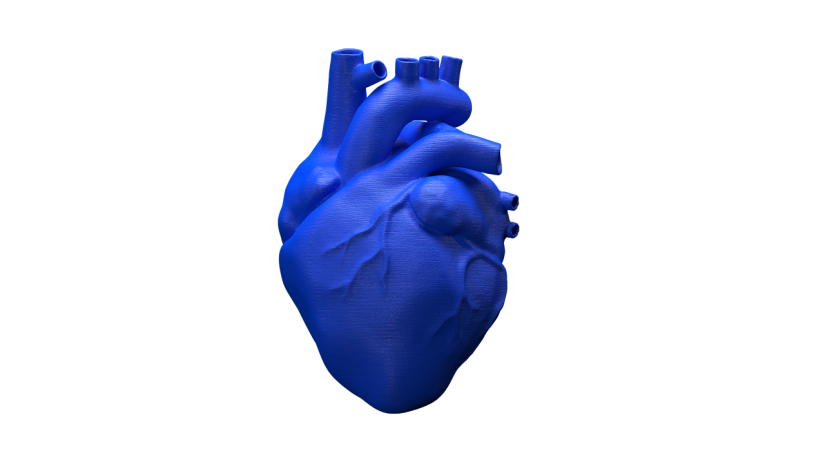

Z-SEMIFLEX

Z-SEMIFLEX is characterized by minimal shrinkage and resistance to greases and chemicals. It is based on TPU 98A which gives your models unique characteristics, including high elasticity and rubber-like properties. Z-SEMIFLEX also exhibits high impact strength which allows you to apply force to a 3D printed model with little risk of damage. These unparalleled qualities make Z-SEMIFLEX ideal not only for prototypes tested in adverse industrial environments, but also for models resembling organs used in medical assessment processes.

Dedicated for: M200 Plus, M300 Plus

Z-ULTRAT

Z-ULTRAT is a material characterized by high impact resistance, which gives your models a uniform surface texture. This all-purpose material allows you to 3D print elements requiring durability, such as end-use parts which, after continued use, keep their initial shape over time. With Z-ULTRAT, you can produce objects with properties comparable to those of models manufactured using injection molding technology, including functional prototypes, test casings, and mechanical parts. Z-ULTRAT allows you to test your tailor-made projects in unlimited ways, in one of twenty-two shades. Models printed with Z-ULTRAT can be post-processed using various methods like sanding, polishing, vaporizing and more.

Dedicated for: M200, M200 Plus, M300, M300 Plus, Inventure*, M300 Dual**

*single-extrusion mode only

**both single- and dual-extrusion modes

Z-ULTRAT Plus

Z-ULTRAT Plus is a material which combines high impact resistance and improved adhesion between individual layers in models. Its qualities provide enhanced durability of 3D printed items, allowing you to create complex mechanisms and strong end-use parts resistant to tearing and breaking off. Z-ULTRAT Plus is based on ABS and therefore is a perfect alternative for this widely known and used by the industry thermoplastic. This material becomes the best choice for many areas, including automotive and manufacturing, where prototypes require high tolerance during impact tests.

Dedicated for: Inventure, M300 Dual*, Endureal**

*both single- and dual-extrusion modes

**single-extrusion mode only

Tips for Storage

It is really important to take good care of the printing material while storing unused spools. Providing proper storage conditions is essential to prevent having a failed print. The quality of material highly influences the final look of the model.

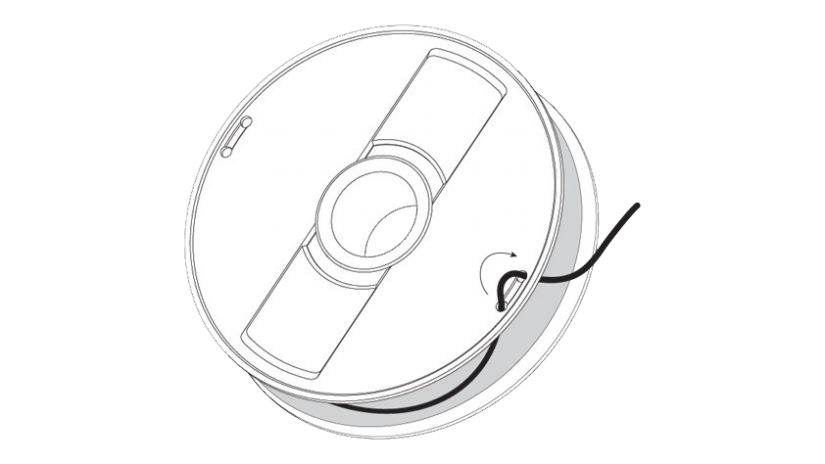

First of all, once you finish the printing process, unload the material, take the spool off of the spool holder, and secure the end of the material as it is shown in the picture to avoid having tangled threads of material. The holes in the spool have been designed especially for this purpose.

Also, keep the spool at room temperature and protect it from sunlight and humidity. Preferably, use vacuum-packaging.