Platform calibration is one of the maintenance procedures that has to be performed before running the printer for the first time and/or whenever you have any printing issues, for example, warping or incomplete first layers. The procedure involves checking the distance between the nozzle and five points on the platform, and tightening/loosening the calibration screws. Platform calibration can lower the risk of problems which may occur during the printing process. This manual shows how to carry out the platform calibration procedure.

| Remember that you should calibrate the platform after carrying out platform maintenance. |

| The following manual shows the M200 platform calibration. For the M300, these procedures are the same. |

Initiating the Calibration

From the menu select Maintenance -> Autocalibration.

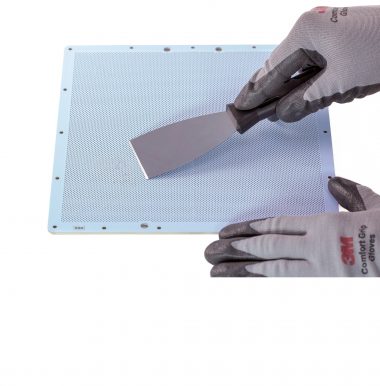

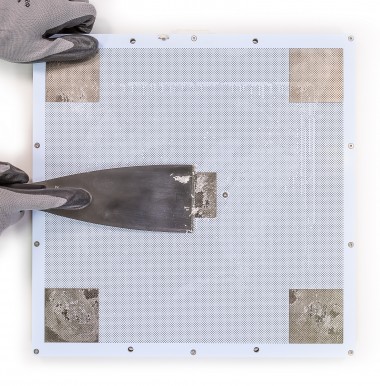

Tightening the Calibration Screws

When the extruder is heated up, press the knob to start the autocalibration.

Follow the instructions on the display. Tighten all calibration screws and press the knob.

The printer will now start to check the distance between the nozzle and the center point of the platform.

Checking the Points at the Back

The printer will now start to check the distance between the nozzle and the points at the back of the platform.

Checking the Points at the Front

The printer will now start to check the distance between the nozzle and the points at the front of the platform.

Distance Corrections

If the printer detects an incorrect distance, it will display instructions on what adjustments should be made.

Once you’ve tightened/loosened the screws, push the knob and the printer will recheck the distances.

When the proper distance for all the points on the plate is set, the printer will finish the calibration and display the calibration results.

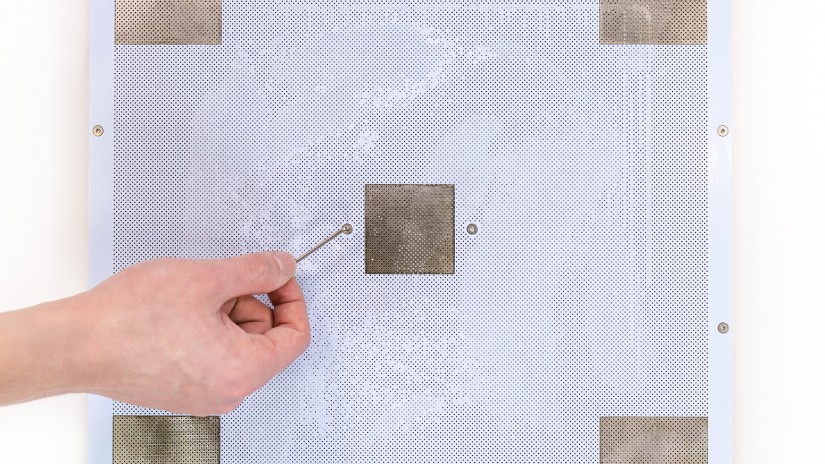

Tightening Platform Screws (M300)

In order to correct the difference in values between the center and the side calibration points, you should tighten/loosen the two platform screws placed next to the center point. If the center point value is 0.2 and one of the side points value is -0.2 (the difference equals or exceeds 0.4), you should tighten the screws, whereas you should loosen them if the center point value is -0.2 and one of the side points value is 0.2.