Axes maintenance is a procedure that can help you resolve problems connected with the extruder’s movement and the quality of your printed parts. If the extruder does not move properly along the guide rails and it makes unusual noises, or the layers in your models become shifted (manual for shifted layers), the axes in your printer need maintenance work. Follow the steps from this manual to see the correct maintenance procedure.

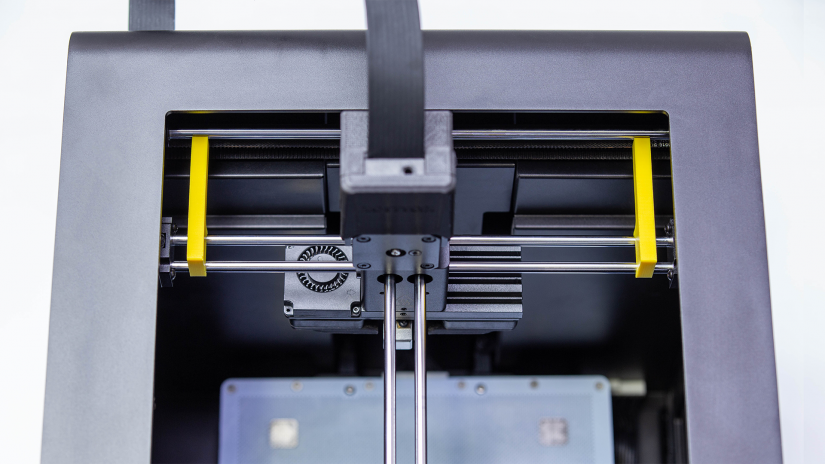

Checking the Axes Using Jigs

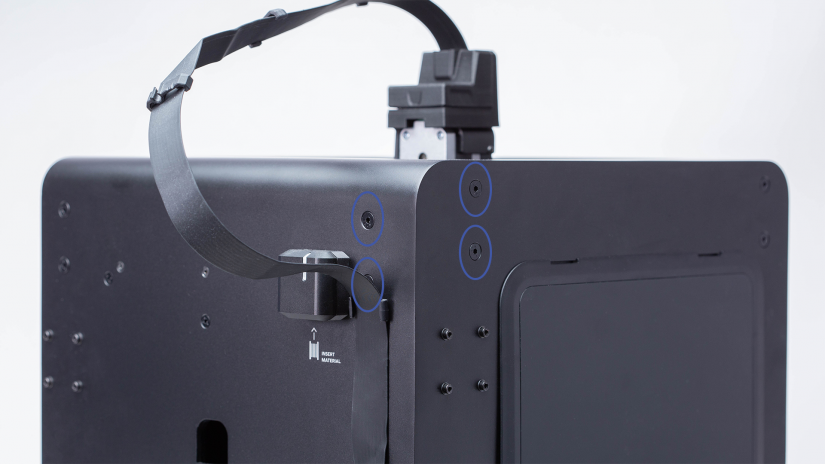

Unscrewing the Z-Axis Cover

Unscrew the four screws that secure the left and right parts of the Z-axis cover. Next, remove the two parts of the cover from the printer. Detailed instructions are available at: Z-axis cover replacement.

Tensing up the Long Belts

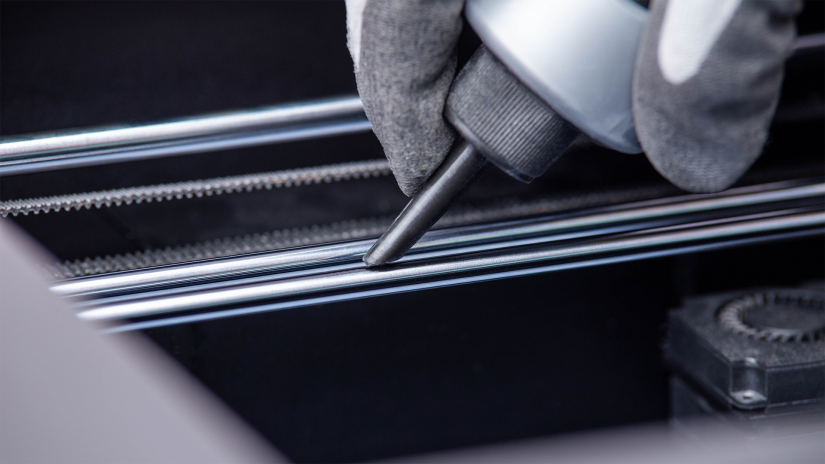

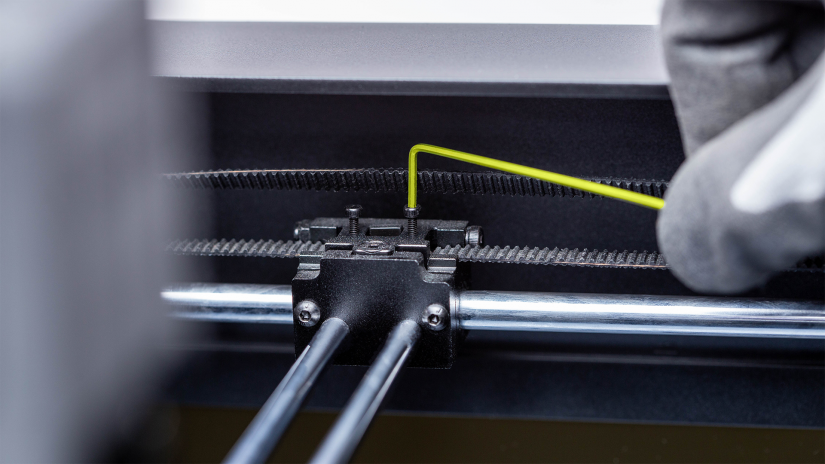

1. Instructions for M200 Plus:

Tug each belt gently to check its tension. If the belt is loose, tighten the two screws placed on the axis block.

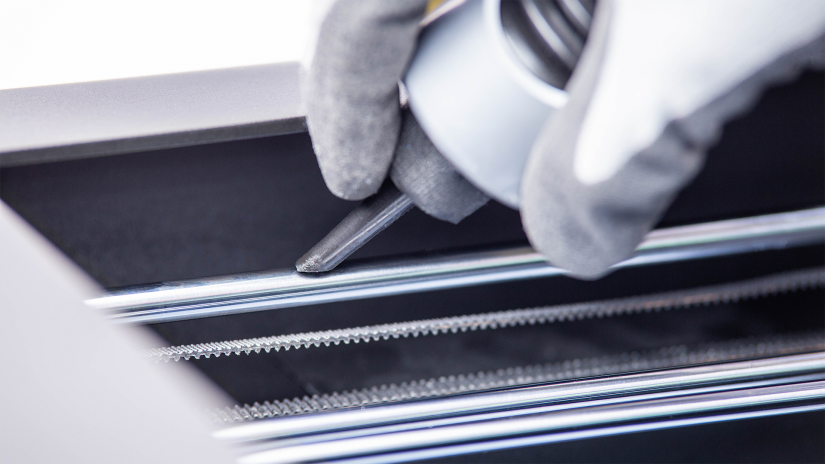

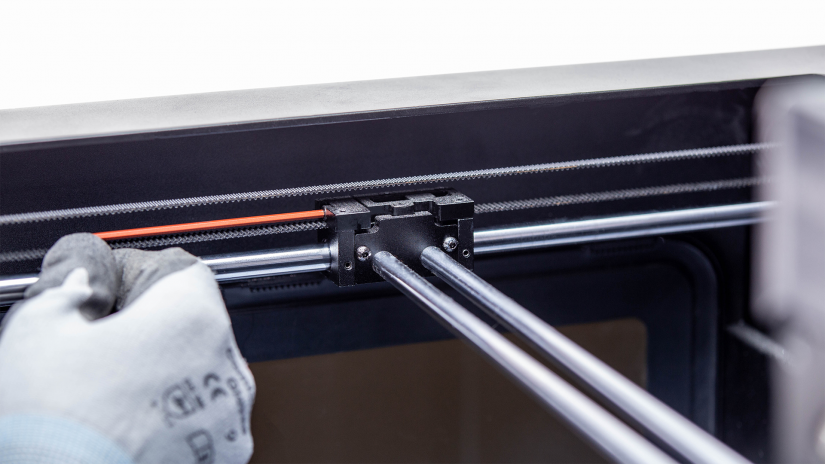

2. Instructions for M300 Plus:

Tug each belt gently to check its tension. If the belt is loose, tighten one screw on the side of the axis block.