Preparing your printer for the first use ensures its proper functioning and makes the whole printing process easier. The following steps show how to properly unpack and set up the machine. This article also shows how to install the firmware as well as how to carry out the platform calibration procedure.

Unpacking

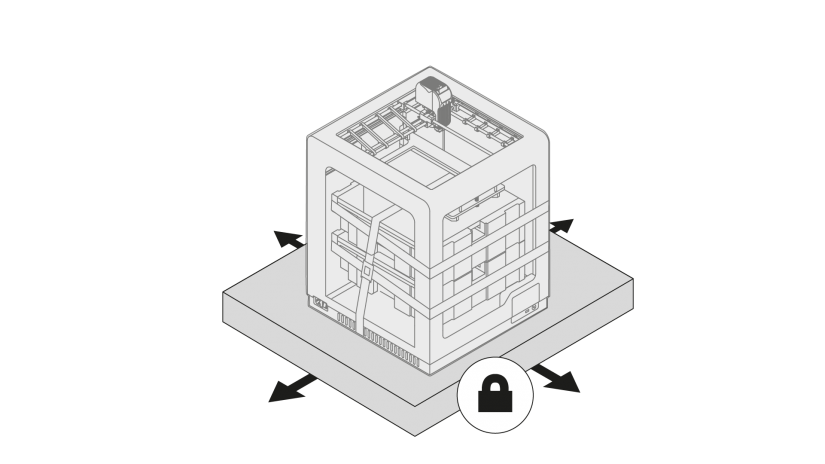

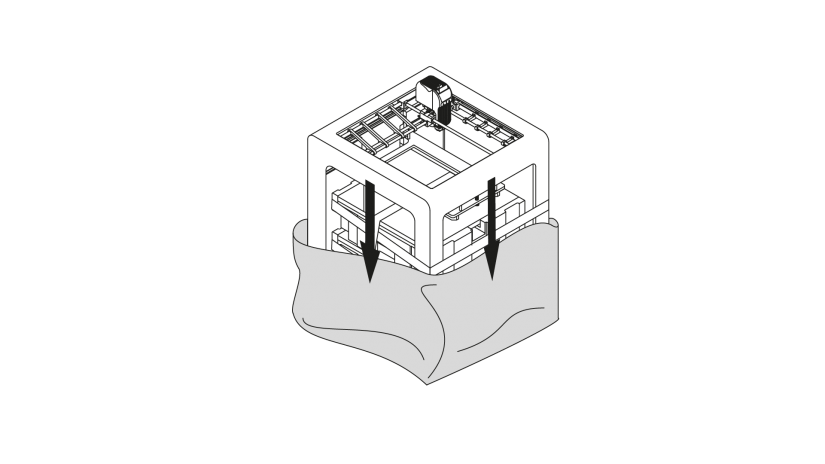

2. Take the 3D printer out of the box. When lifting or moving the printer, do not grab:

a. drive belts

b. shipping clips

c. extruder

Due to the printer's weight, Zortrax M300 Dual should be taken out of the box or moved by two people.

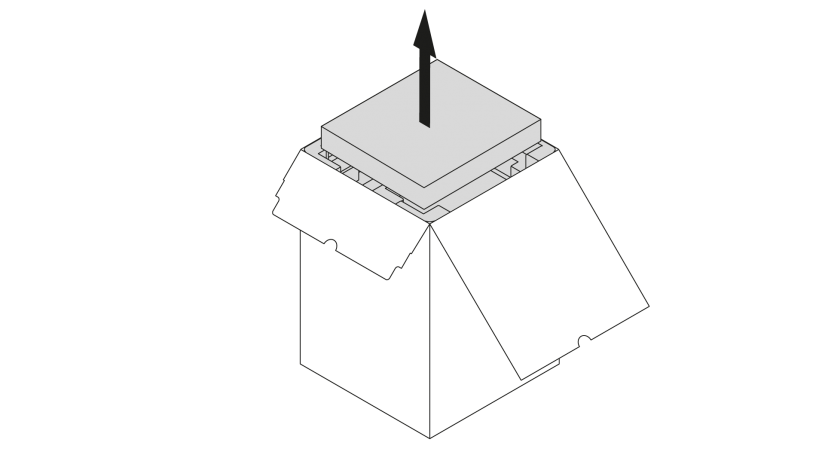

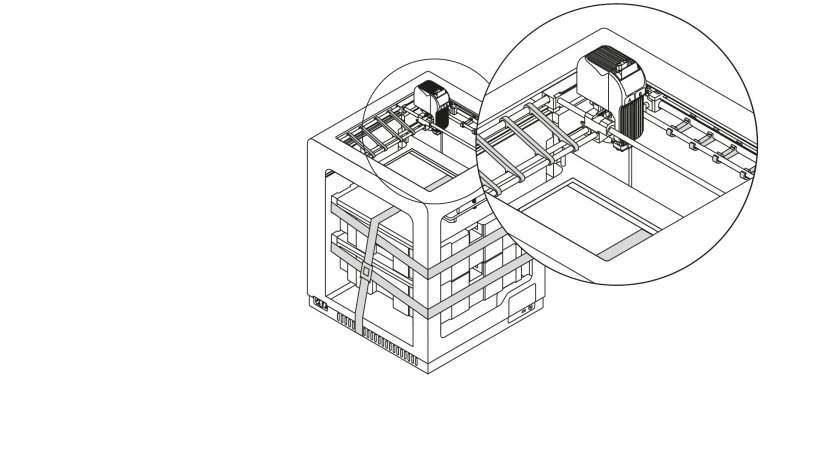

1. Open the box. Remove the upper cushioning and boxes with accessories.

2. Take the 3D printer out of the box. When lifting or moving the printer, do not grab:

a. drive belts

b. shipping clips

c. extruder

Due to the printer's weight, Zortrax M300 Dual should be taken out of the box or moved by two people.

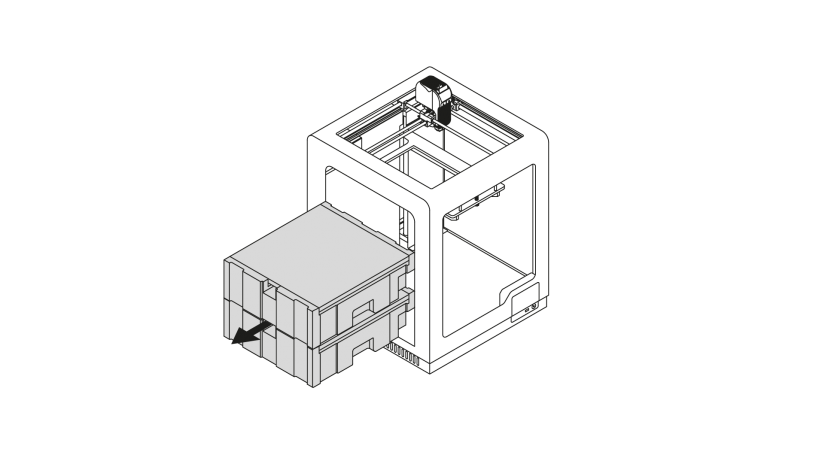

3. Place the 3D printer on a flat and stable surface.

Setting Up

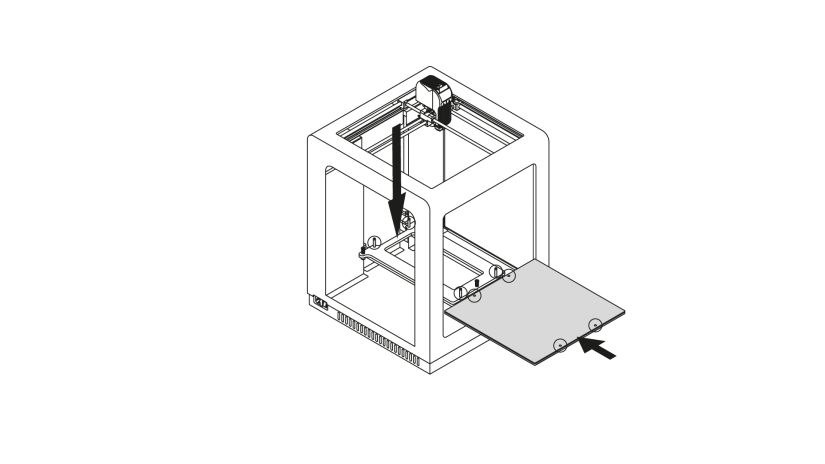

1. Lower the heatbed mount by pressing the place marked with an arrow. Next, install the build platform onto the bolts marked in the graphic. Remember to install the platform with the perforated plate directed up.

1. Lower the heatbed mount by pressing the place marked with an arrow. Next, install the build platform onto the bolts marked in the graphic. Remember to install the platform with the perforated plate directed up.

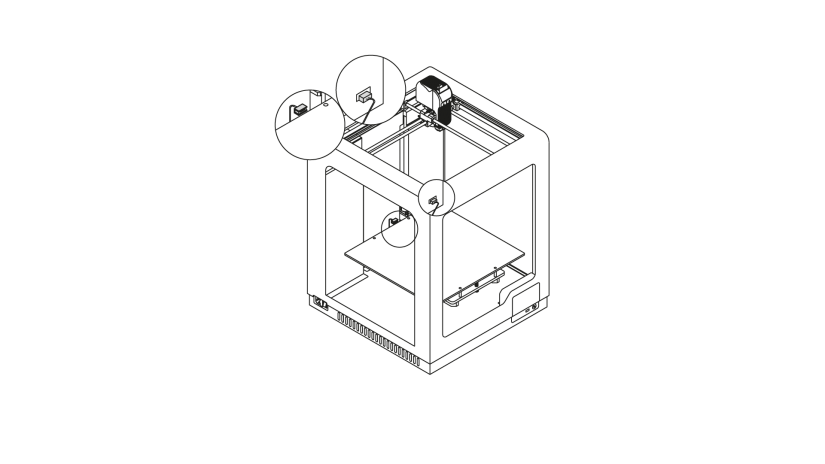

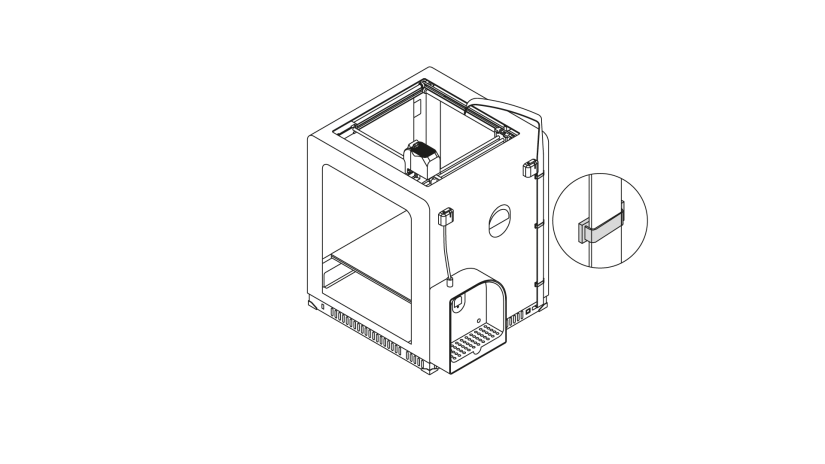

2. Plug the heatbed cable into the platform and into the adapter placed in the Z-axis cover.

3. Unpack the material box and secure it to the back of the printer with the two screws. Next, attach the material guide to the material B endstop.

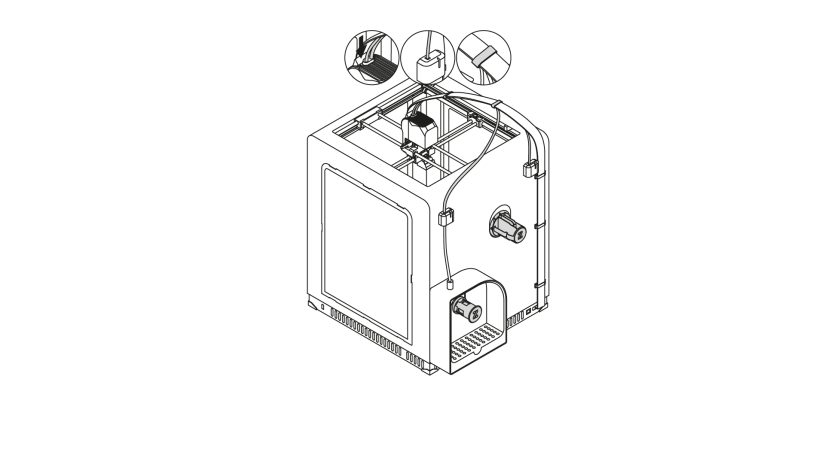

1. Attach the extruder cable clamps at the back of the printer. Place the extruder cable in the clamps.

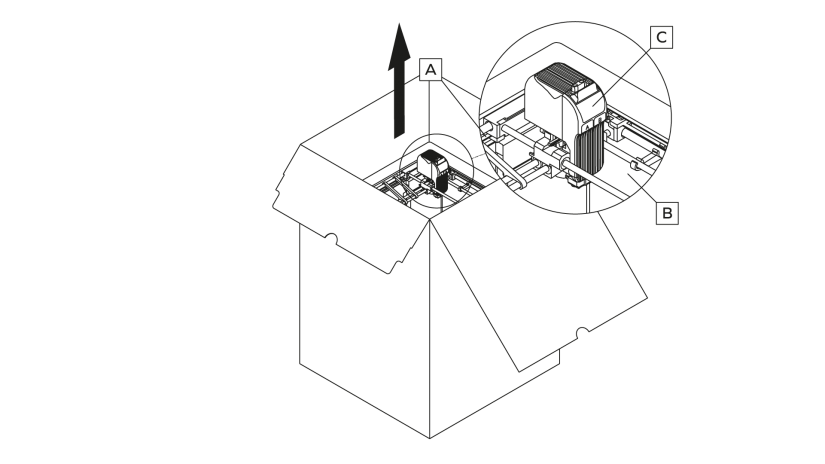

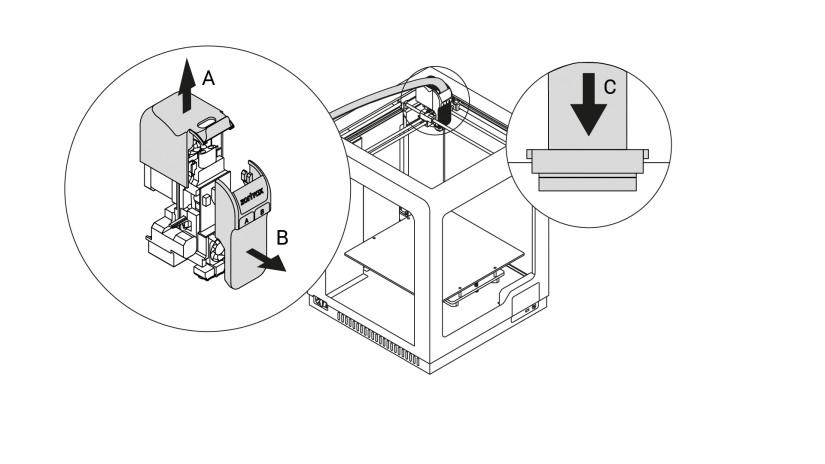

2. Remove the extruder top cover by pulling it upwards (A) and remove the front cover (B). Plug in the extruder cable (C). Place the front cover in its place and reattach the top cover.

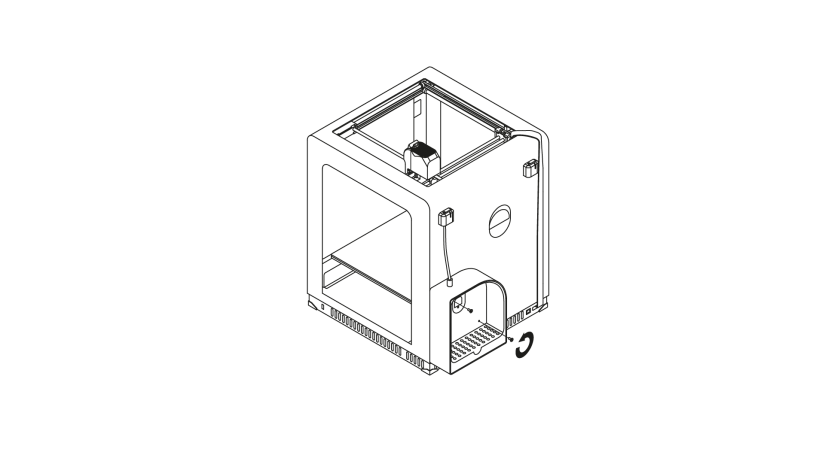

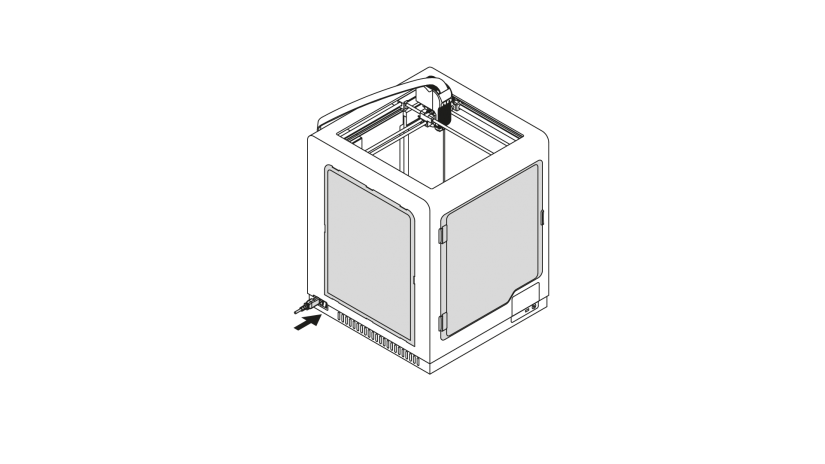

3. Remove the protective cap from the camera inside the printer. Next, install all side covers. For more details, see the manual: side covers installation. Next, plug in the power cable.

1. Attach the extruder cable clamps at the back of the printer. Place the extruder cable in the clamps.

2. Remove the extruder top cover by pulling it upwards (A) and remove the front cover (B). Plug in the extruder cable (C). Place the front cover in its place and reattach the top cover.

3. Remove the protective cap from the camera inside the printer. Next, install all side covers. For more details, see the manual: side covers installation. Next, plug in the power cable.

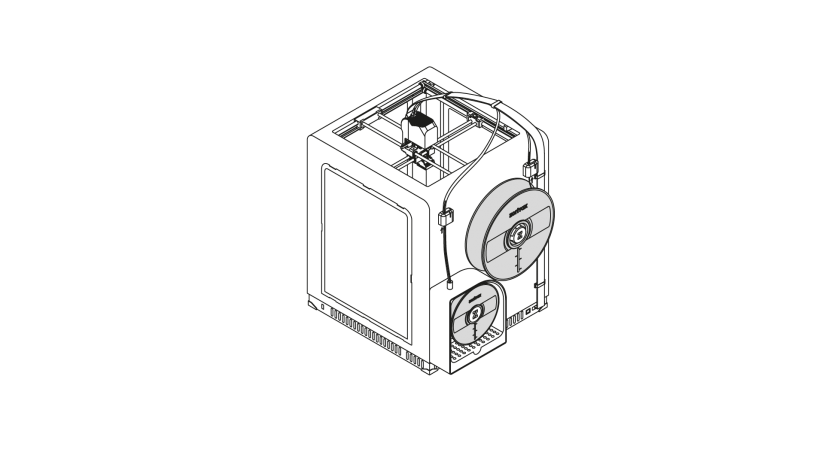

1. Attach the two spool holders at the back of the printer. Next, attach the two material guides to the extruder and to the material endstops. Secure the two guides to the extruder cable using the material guide clamps.

1. Attach the two spool holders at the back of the printer. Next, attach the two material guides to the extruder and to the material endstops. Secure the two guides to the extruder cable using the material guide clamps.

2. Place the spools on the holders. The spools should rotate anti-clockwise. Feed the materials into the extruder through the material endstops and the material guides.

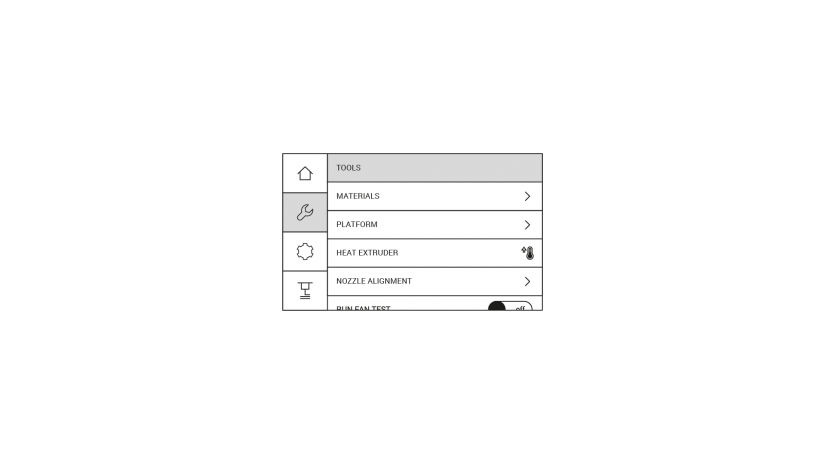

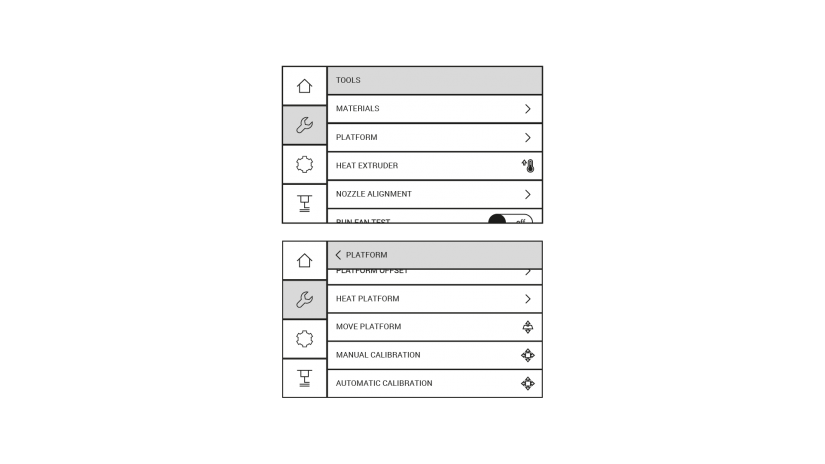

1. To calibrate the platform, select TOOLS, PLATFORM, and then AUTOMATIC CALIBRATION or MANUAL CALIBRATION (requires preparing paper in the A4 size) from the menu. Follow the instructions displayed on the screen.

1. To calibrate the platform, select TOOLS, PLATFORM, and then AUTOMATIC CALIBRATION or MANUAL CALIBRATION (requires preparing paper in the A4 size) from the menu. Follow the instructions displayed on the screen.

2. Load the material using options from the MATERIALS menu. Next, carry out NOZZLE ALIGNMENT calibration. Follow the instructions displayed on the screen.