The perforated plate is an essential part of the build platform, which increases models’ adhesion to the platform surface during the whole printing process. However, the perforated plate can become worn over time and material residues which remain on its surface can influence the quality of 3D printed parts. Once you notice considerable signs of wear and tear on the plate’s surface, such as visible scratch marks or deformations, consider replacing the perforated plate. Also, the plate requires replacement when you have problems with completing the platform calibration procedure or when the small connector has been damaged. This manual shows the correct replacement procedure.

Unplugging the Power Cable

Turn off the printer and unplug the power cable.

Unplugging the Heatbed Cable (from the Z-axis Cover)

Unplug the heatbed cable from the Z-axis cover.

Platform Removal

Remove the platform with the heatbed cable from the printer.

Unplugging the Heatbed Cable (from the Platform)

Unplug the heatbed cable from the platform.

Unscrewing the Perforated Plate

Unscrew the screws to separate the perforated plate from the heatbed.

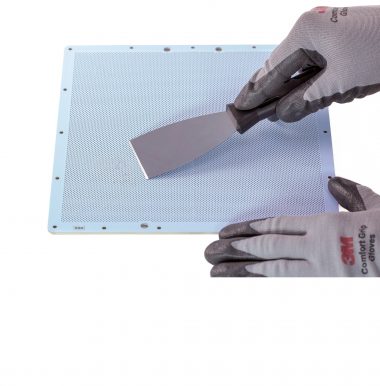

Cleaning the Heatbed

Remove material remains from the heatbed using a piece of cloth or, if it is necessary, use a spatula.

Securing the Perforated Plate

Secure the new perforated plate to the heatbed with the screws.

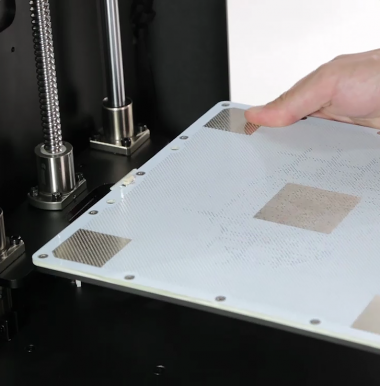

Platform Installation

Place the heatbed cable behind the heatbed mount and install the platform back in the printer.

Plugging the Heatbed Cable (into the Z-axis Cover)

Plug the heatbed cable into the Z-axis cover.

Plugging the Power Cable

Plug the power cable in.