A glass plate is especially recommended for raftless 3D printing as it provides your models with a better quality of bottom surfaces. The glass plate can easily be installed on the heatbed using special clips and screws once the perforated plate is removed. You can use the glass plate with the M300 Dual, M200 Plus as well as M300 Plus. If you want to switch from the perforated plate to the glass plate, follow the instructions below.

| For the M Series Plus devices, printing with the glass plate requires updating the firmware to the 2.0 version or newer. |

| M200 Plus/M300 Plus Platform Calibration Remember that once you install the glass plate in your printer, you will only be able to carry out manual calibration. |

Unplugging the Power Cable

Turn the printer off and unplug the power cable.

Platform removal

Unplug the heatbed cable and carefully remove the platform from the printer.

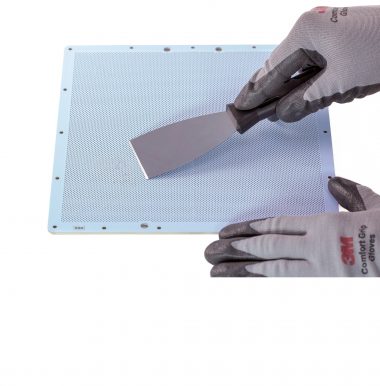

Perforated Plate Removal

Unscrew the twelve screws that secure the perforated plate to the heatbed. Next, separate the plate from the heatbed.

Cleaning the Heatbed

Clean the heatbed from material residues using a piece of cloth.

Pogo Pin Module Removal*

Turn the heatbed over and unscrew the two screws that secure the pogo pin module. Next, remove the module.

*This step applies only to the M200 Plus.

Glass Plate Installation

Place the glass plate on the heatbed.

Securing the Glass Plate, part 1

Install the four corner clips and secure them with the screws.

Securing the Glass Plate, part 2

Install the two push-on side clips.

Platform Installation

Place the platform in the printer and plug the heatbed cable in. Next, start the platform calibration procedure using the options from the menu*.