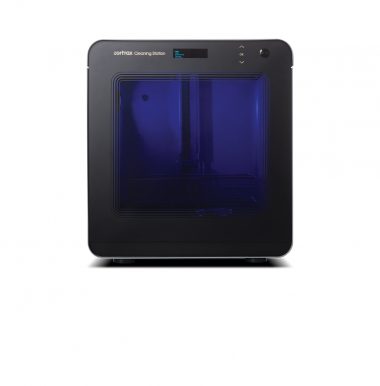

Zortrax Apoller is a smart vapor smoothing device that automatically removes visible layering from FDM 3D prints. Our short tutorial will inform you on how to quickly set it up right after taking it out of the box and how to perform your first automated smoothing process of your 3D printed models.

The smoothing process is entirely automated and run by proprietary algorithms managing temperature, pressure, and concentration of solvent’s vapors at all times. Once you take the Apoller out of the box, all you need to do is follow the simple steps shown in the video. First, once you finish 3D printing your model, it has to be placed inside the smoothing chamber. When this is done, the chamber is heated enough to vaporize the solvent deposited in a sink below the glass tray. Vapors are then circulated spiraling upwards to evenly cover the model. Finally, Zortrax Apoller dries the 3D prints out to make them ready to use straight out of the chamber.

| Only pure acetone and pure butanone (MEK) are supported and safe to use. Using other solvents may be dangerous and should not be attempted. It will also result in voiding the warranty. |

| Every unit requires an annual inspection conducted by the Zortrax Authorized Service to keep the ATEX certification valid and ensure safe operation of the device. |