Z-PETG and Z-GLASS are characterized by improved durability and can be used for industrial prototyping in many sectors. However, both materials are heat sensitive. Therefore, is is possible that your printer can have problems with extrusion and you can notice some quality issues in your prints, including material deficiencies. There are some measures which can help you avoid these problems and ensure a problem-free printing process. Follow the tips from this article to succeed when 3D printing with Z-PETG and Z-GLASS.

Printing Conditions

First of all, printing with Z-PETG and Z-GLASS requires providing proper conditions in the print room. The temperature should not exceed 28° C [82° F]. When preparing a file for 3D printing in Z-SUITE, make sure to always check the Auto box in the Fan speed section. It is not advisable to adjust the Fan speed manually.

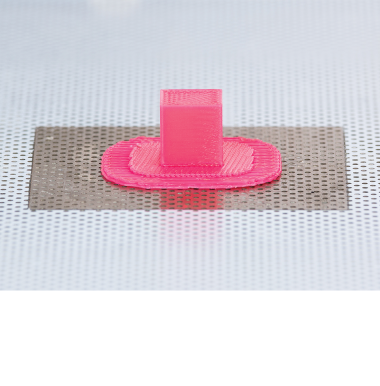

To reduce shrinkage, it is advisable to create a printing chamber with the use of Side Covers and a HEPA Cover. These accessories have been designed to support the printing process with materials of a high shrinkage rate.

Printer Maintenance

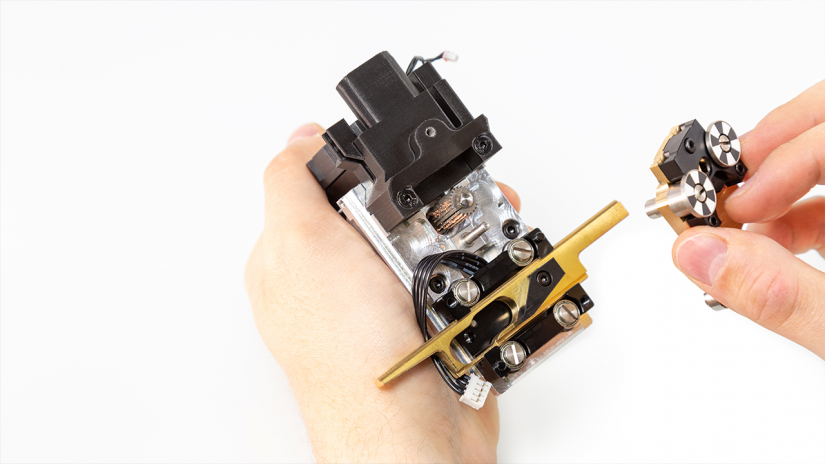

Once you notice that extrusion in your printer is not as effective as it should be, make sure that the model material nozzle and hotend are not clogged, and if it is necessary, clean both components.

Unscrew the nozzle counterclockwise using the nozzle key (when viewed from below).

NOTE! Unscrew the nozzle while the extruder is hot.

Load the material using the options from the menu. If the material is being extruded from the hotend, the nozzle you have just removed needs to be cleaned or replaced. If the material is not being extruded, the hotend module needs to be cleaned or replaced.

Also, make sure that there are no material remains on the extruder motor shaft. Carry out extruder maintenance according to instructions from this manual.

After-Print Tips

To prevent further printing problems, unload Z-PETG or Z-GLASS immediately after the printing process. The materials should not be left loaded in the hotend as they become more difficult to extrude after some time. Additionally, once you finish printing, print a small-sized object using Z-ULTRAT (or ABS) to remove residues from the nozzle and hotend that can accumulate during when printing with Z-PETG or Z-GLASS.

If the above steps do not help and you still have problems with extrusion, the nozzle or the hotend module should be replaced.