Z-NYLON (PA12) is a versatile material that exhibits high impact and abrasion resistance. Its properties also include resistance to high temperatures and moderate chemical substances. Z-NYLON is fully suited for technical and mechanical parts, such as toothed gears, guides, slide bearings, or functional tools. However, Z-NYLON is a demanding material in terms of storage and printing process conditions. There are several measures to be taken to make the printing process easier and problem-free. This article provides all the information you need to know to succeed when 3D printing with Z-NYLON.

Storage & Preparation

Z-NYLON is highly hydroscopic and shouldn’t be stored without protection in humid environments for a long time. Unused spools have to be stored in an airtight container with a moisture absorber. Otherwise, the filament will absorb moisture from air which can cause problems such as stringing or low surface quality of printed parts. Also, the color of the filament can fade or become dull.

To remove moisture from the filament, perform a drying procedure at 90 °C [194 °F] for 2 hours.

Hardware Requirements

To create the best printing environment for Z-NYLON, it is best to equip your printer with a separate hotend and a perforated plate that will be dedicated only for printing with this material. These parts should be new and not used with other materials.

Also, avoid using adhesive substances with the new perforated plate.

Model Preparation Tips

As all nylon-based materials, Z-NYLON is highly prone to warping. That’s why, while preparing your model in Z-SUITE, go to Advanced section in the Print settings step and set the Fan speed to 0%.

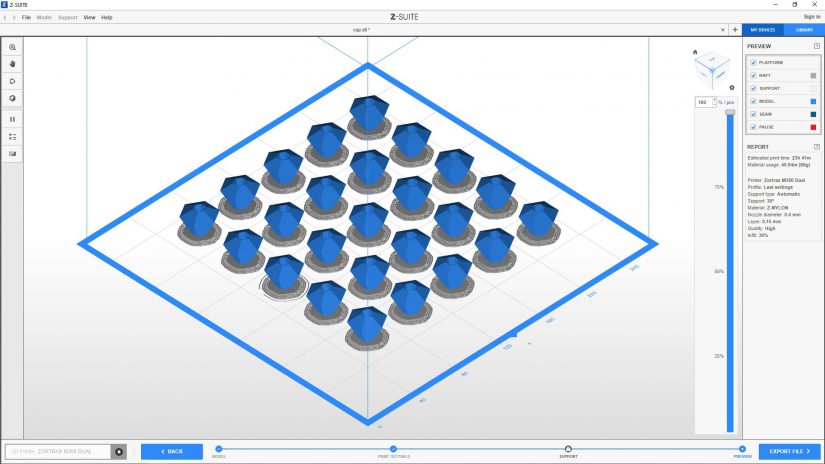

If you’re preparing several small models for printing, make sure to separate them in the workspace so that each item has its own raft structure. This way, a smaller printing area can reduce the risk of warping.

Printing Process Requirements

While printing with Z-NYLON, it is recommended to provide proper conditions in the print room. First of all, make sure that there are no draughts in your work area. Strong airflows cause warping and may damage your print. Also, avoid printing in humid conditions. Due to its high shrinkage, Z-NYLON is not recommended for printing large geometric models with steep slopes in the Z axis. In general, models with walls that are perpendicular to the platform will be less prone to warping. Still, it is advisable to add support structures to all angles and overhanging parts of your model.

To reduce shrinkage, it is advisable to create a printing chamber with the use of Side Covers and a HEPA Cover. These accessories have been designed to support the printing process with materials of a high shrinkage rate.

Lastly, remove any residues of material extruded during the pre-print calibration. This will facilitate adhesion of raft and the whole model to the perforated plate.