BASF Ultrafuse® PPSU is an industrial high-performance 3D printing filament with flame-retardancy properties. It is characterized with excellent thermal stability, good chemical resistance, and high strength. To achieve successful prints with Ultrafuse® PPSU, there are a few guidelines that you must follow when using and storing the filament. First of all, it is crucial to perform filament drying before each printing process. The procedure reduces the amount of moisture in the filament which, if not removed, can have a negative impact on the printing process. You can perform filament drying in the Endureal’s chamber or in any other dryer available on the market. Below there are tips for carrying out the drying procedure.

Performing Filament Drying

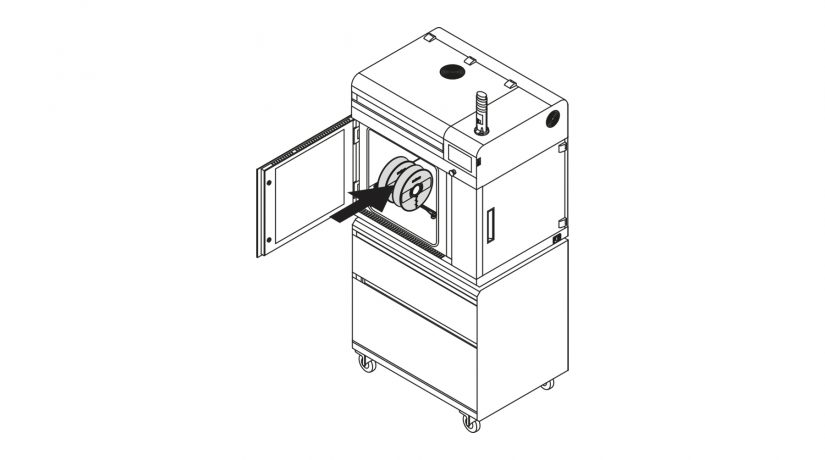

2. Next, put the spool on the platform in the chamber. For better results, leave the spool in a vertical position. You can perform the drying procedure with several spools at the same time.

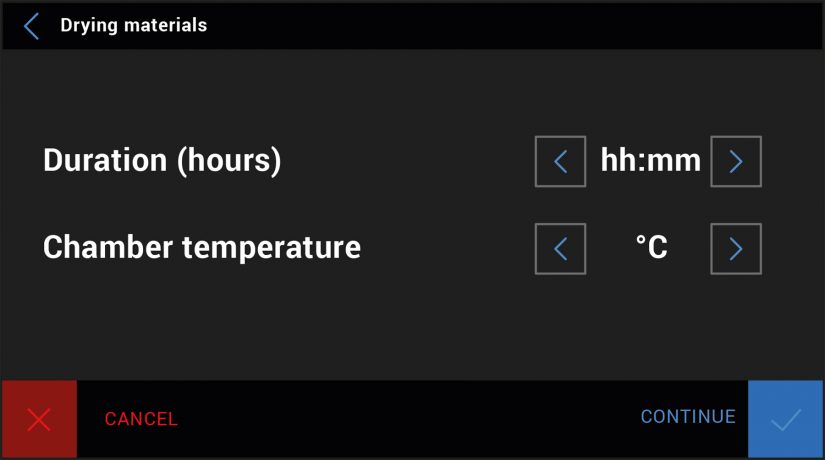

3. Important: The temperature settings provided below cannot be exceeded as it may lead to filament deformation.

The duration of drying depends on the level of moisture the material has absorbed.

Enter the temperature and time settings, and start the process. Recommended values are: 120 °C and 48 hours. Once the process has finished, the material is ready to be taken out of the chamber and loaded into the extruder. Optionally, you can use a vacuum dryer with 125 °C and 8 hours settings.

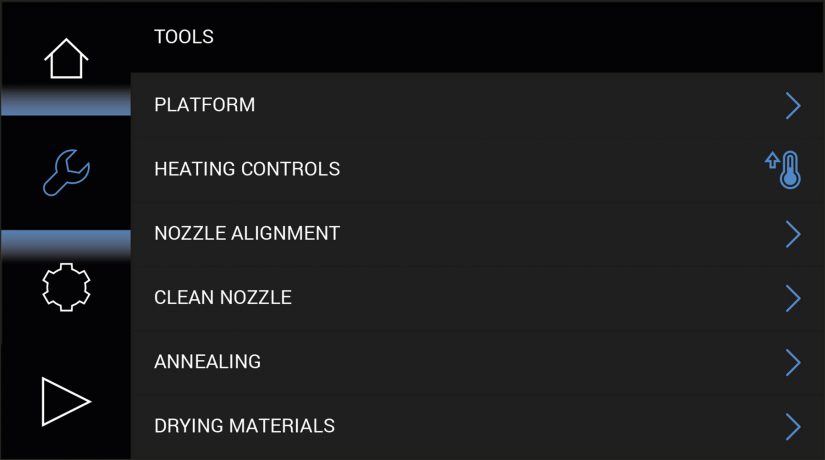

1. To start filament drying, select Tools and Drying materials.

2. Next, put the spool on the platform in the chamber. For better results, leave the spool in a vertical position. You can perform the drying procedure with several spools at the same time.

3. Important: The temperature settings provided below cannot be exceeded as it may lead to filament deformation.

The duration of drying depends on the level of moisture the material has absorbed.

Enter the temperature and time settings, and start the process. Recommended values are: 120 °C and 48 hours. Once the process has finished, the material is ready to be taken out of the chamber and loaded into the extruder. Optionally, you can use a vacuum dryer with 125 °C and 8 hours settings.

Storage

It is really important to take good care of the printing material while storing unused spools. Providing proper storage conditions is essential to prevent having a failed print. The quality of material highly influences the final look and properties of the model.

First of all, once you finish the printing process, unload the material, take the spool off of the holder, and secure the end of the material as it is shown in the picture to avoid having tangled threads of material. The holes in the spool have been designed especially for this purpose.

Also, keep the spool at room temperature and protect it from sunlight and humidity. Preferably, use vacuum-packaging.

3D Printing Guidelines

Here are a few 3D printing guidelines to follow when using Ultrafuse® PPSU:

1. Make sure the platform has been properly calibrated.

2. To increase models’ adhesion during the printing process, evenly apply a thin layer of Magigoo HT adhesive onto the platform when it is cold and cleaned from any residues.