Filament drying is a pre-printing treatment which is required for some of the high-temperature materials – Z-PEI 1010, Z-PEI 9085, and Z-PEEK. The procedure reduces the amount of moisture in the material which, if not removed, can have a negative impact on the printing process, and the model’s thermal and mechanical properties. Filament drying can be performed in the Endureal’s chamber or in any other dryer available on the market. This article provides tips for carrying out the drying procedure.

Performing Filament Drying

2. Next, put the spool on the platform in the chamber. For better results, leave the spool in a vertical position. You can perform the drying procedure with several spools at the same time.

1. To start filament drying, select Tools and Drying materials.

2. Next, put the spool on the platform in the chamber. For better results, leave the spool in a vertical position. You can perform the drying procedure with several spools at the same time.

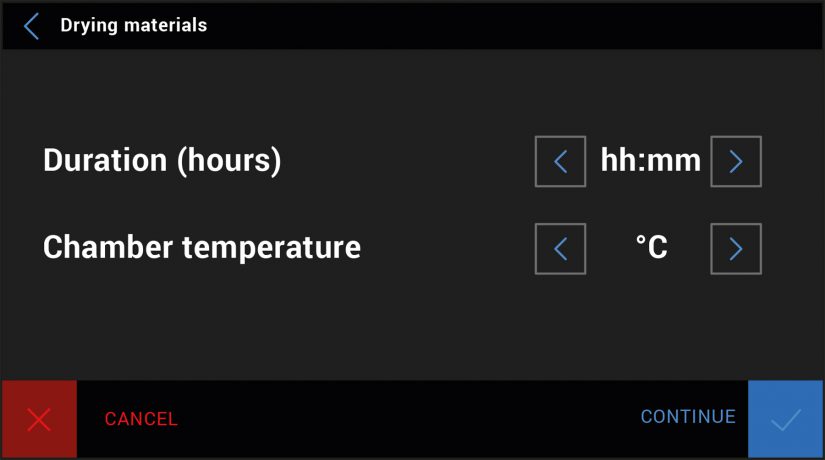

3. Enter the temperature and time settings appropriate for the material you are about to dry, and start the process. Once the process has finished, the material is ready to be taken out of the chamber and loaded into the extruder.

Setting Time and Temperature

Important: The temperature settings provided below cannot be exceeded as it may lead to filament deformation.

The duration of drying depends on the level of moisture the material has absorbed. Minimum drying time should be at least 4 hours.

Make sure that there is good air quality in the area where you process or dry high-temp filaments. For safety reasons, it is recommended to install a smoke detector nearby.

1. Z-PEI 1010 and Z-PEI 9085 should be dried at 150 °C (302 °F) for at least 4 hours.

2. Z-PEEK and Z-SUPPORT High-Temp should be dried at 120 °C (248 °F) for at least 4 hours.