Axes maintenance – method with JIGS – is a procedure that can help you resolve problems connected with the extruder and the quality of your printed parts. If the extruder does not move freely and makes unusual sounds, or if you have problems with shifted layers and deformations on your models, and the measurement accuracy between the design and the final print cannot be achieved, the axes in your printer need maintenance work. Follow the steps from this manual to eliminate the mentioned problems and achieve the desired quality of prints.

6

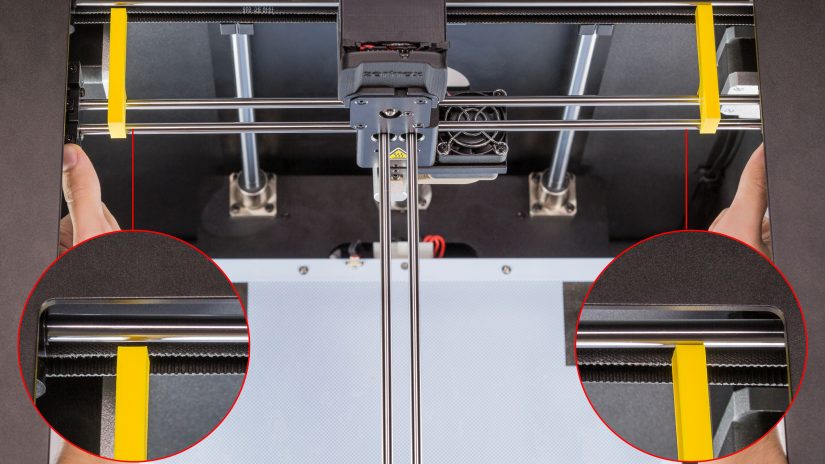

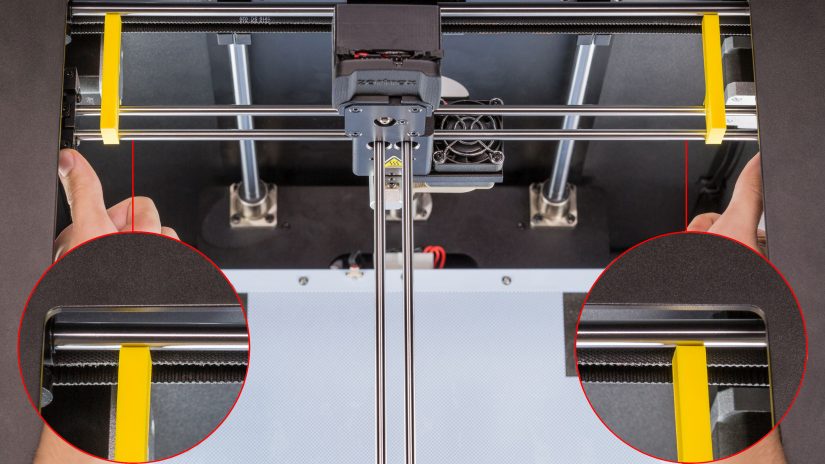

Tensing up the Belts

Check the belts for proper tension.

a) Check both the upper and lower belt. If the belts are properly tense, you can finish the maintenance work.