Axes maintenance is a procedure that can help you resolve problems connected with the extruder and the quality of your printed parts. If the extruder does not move properly along the guide rails and it makes unusual noises, or if layers in your models become shifted, the axes in your printer need maintenance work. Follow the steps from this manual to see the correct maintenance procedure. Keep in mind that you do not have to follow all steps at once.

Unplugging the Power Cable

Unplug the power cable.

Belts Maintenance

There are short and long belts in your printer. The belts have to tense in order to produce successful prints.

Tug each belt gently to check its tension. If the belt is loose, follow the next steps from this manual.

Tensing the Short Belts

Loosen the four screws that secure the motor using a 2.5mm Allen key.

Press down the motor by hand to tense up the belt. Tighten the screws while the motor is still being pressed down.

Tensing the Long Belts

Move the extruder to the center position. Tighten the screws on the axis block using a 1.5mm Allen key.

X/Y Axis Motor Pulleys Maintenance

If the motor is running but the belt placed on the motor pulley does not move, the screws on the pulley have to be tightened.

Unplugging the Motor Cable

Unplug the motor cable.

Unscrewing the Axis Motor

Unscrew the four screws that secure the motor using a 2.5mm Allen key.

Axis Motor Removal

Remove the motor distance piece and remove the motor.

Tightening the Screws on the Motor Pulley

Tighten the screws on the motor pulley using a 2mm Allen key.

Axis Motor Assembly, part 1

Put the belt on the motor pulley and install it with the distance piece.

Axis Motor Assembly, part 2

Insert the four screws into the holes in the housing and tighten them slightly.

Securing the Axis Motor

Press down the motor by hand to tense up the belt. Tighten the screws while the motor is still being pressed down.

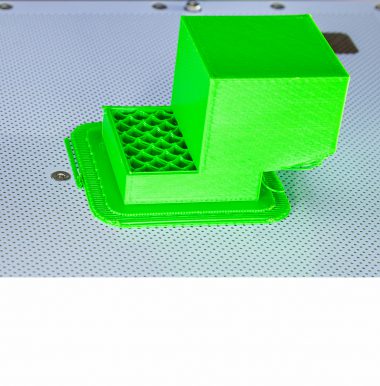

Axes Pulleys Maintenance

There are 2 drive pulleys on each axis, which are placed next to the long belts (8 drive pulleys altogether). Each pulley has two screws. Tighten each screw on each drive pulley (16 screws altogether).

Lubricating the Guide Rails

Regular lubrication is important to reduce friction on the bearings and extend the bearings’ life span.

Use silicone oil to lubricate the guide rails on the X and Y axes. Apply a thin layer of oil on each rail.

Remember to lubricate the Z axis rails as well.

Only trapezoidal screw in HW2 can be lubricated.

Plugging the Power Cable

Plug the power cable in.