The nozzle is an element used to direct a flow of material throughout the entire printing process. If you encounter problems with extrusion during either material loading or printing, the nozzle may be clogged and require cleaning (see the manual – nozzle cleaning) or even replacement. Also, the nozzle needs to be replaced if you notice burn marks or material deficiency in the model’s structure. Follow these steps in case cleaning does not help.

| The following manual shows the M200 repair work. For the M300, these procedures are the same. |

Unloading the Material

From the main menu select Material and then Unload the material option. The extruder will start to heat up automatically. Once it is hot, the motor will start to unload the material.

Nozzle Removal

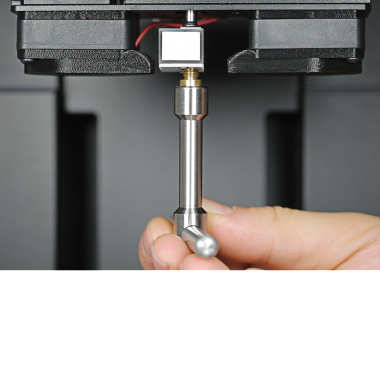

Unscrew the nozzle counterclockwise (when viewed from below). Use the nozzle key from the Starter Kit box. Removing the nozzle should take place while the extruder is still hot. When the nozzle is loose, remove it using pliers.

Unplugging the Power Cable

Turn off the printer and unplug the power cable. Wait about 15 minutes and let the machine cool down.

Nozzle Assembly

Install the new nozzle in the hotend and screw it in clockwise using the nozzle key (when viewed from below).